How to manage materials in the SMT production process?

August 25,2023With the rapid development of artificial intelligence, intelligent manufacturing is constantly being updated and reshaped. Intelligent manufacturing is deeply integrated with big data, artificial intelligence, cloud computing, AIoT and other technologies to realize the automation, intelligence and digitization of the production process.

Future Att face the field of intelligent storage in the electronics industry, combining intelligent storage equipment and iwmcs intelligent storage management system, to provide factories with intelligent and efficient storage solutions, improve factory production efficiency, and create maximum value for customers.

Material management during production:

inventory management

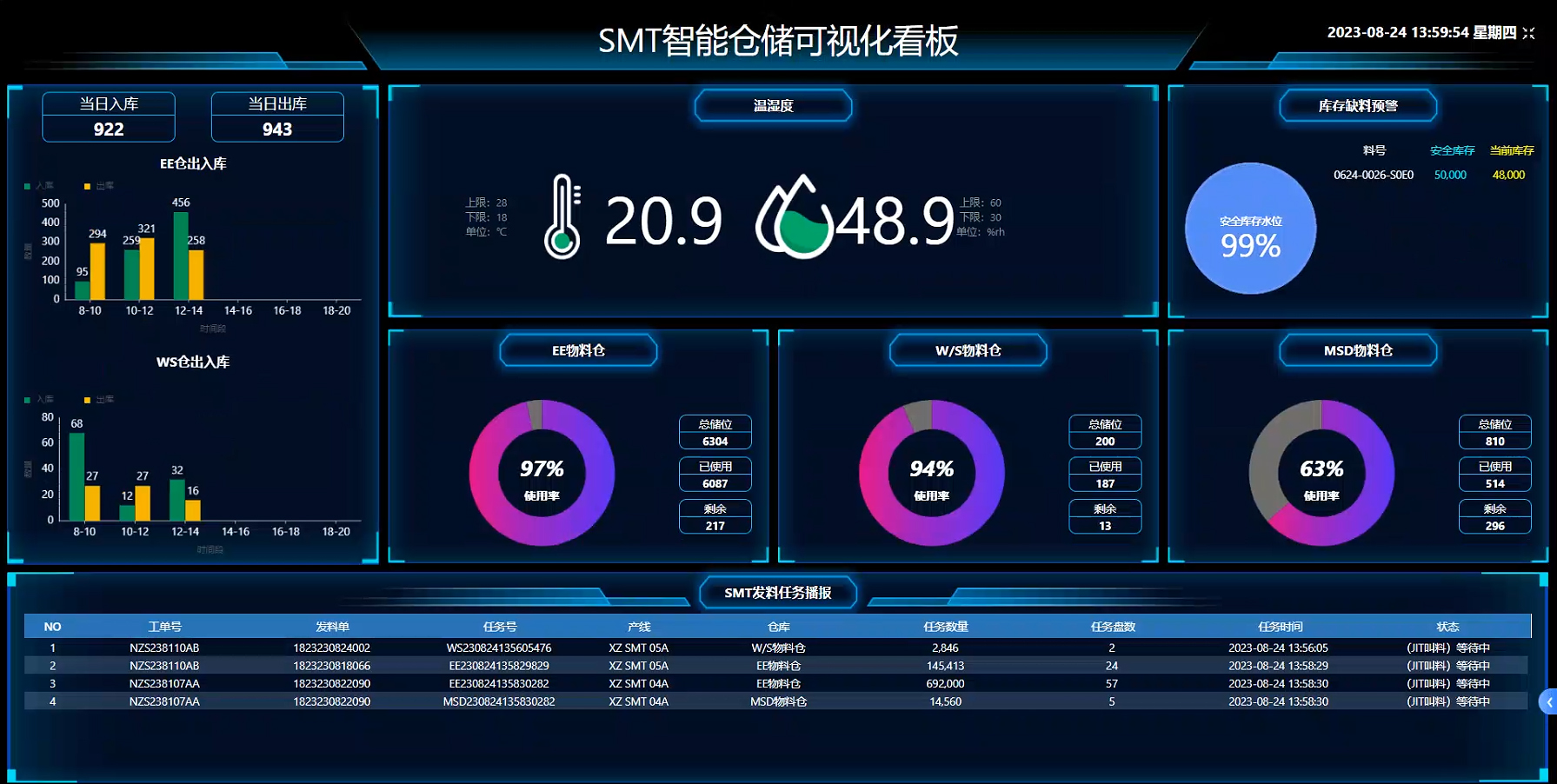

Future Att will use the IWMCS intelligent warehouse management system to maintain inventory accuracy, view and monitor inventory management in real time, and reorder materials in advance when encountering inventory shortages.

Material inspection

Conduct visual inspections, spot checks, or tests to verify the quality of components and PCBs to ensure incoming materials meet quality standards.

Storage specification

Protect electronic components from static electricity by placing them in a humidity-controlled environment. The smt smart warehouse and smart material rack provided by Future Att will meet the requirements of components for special environments such as dustproof, moistureproof, and moistureproof.

Material management

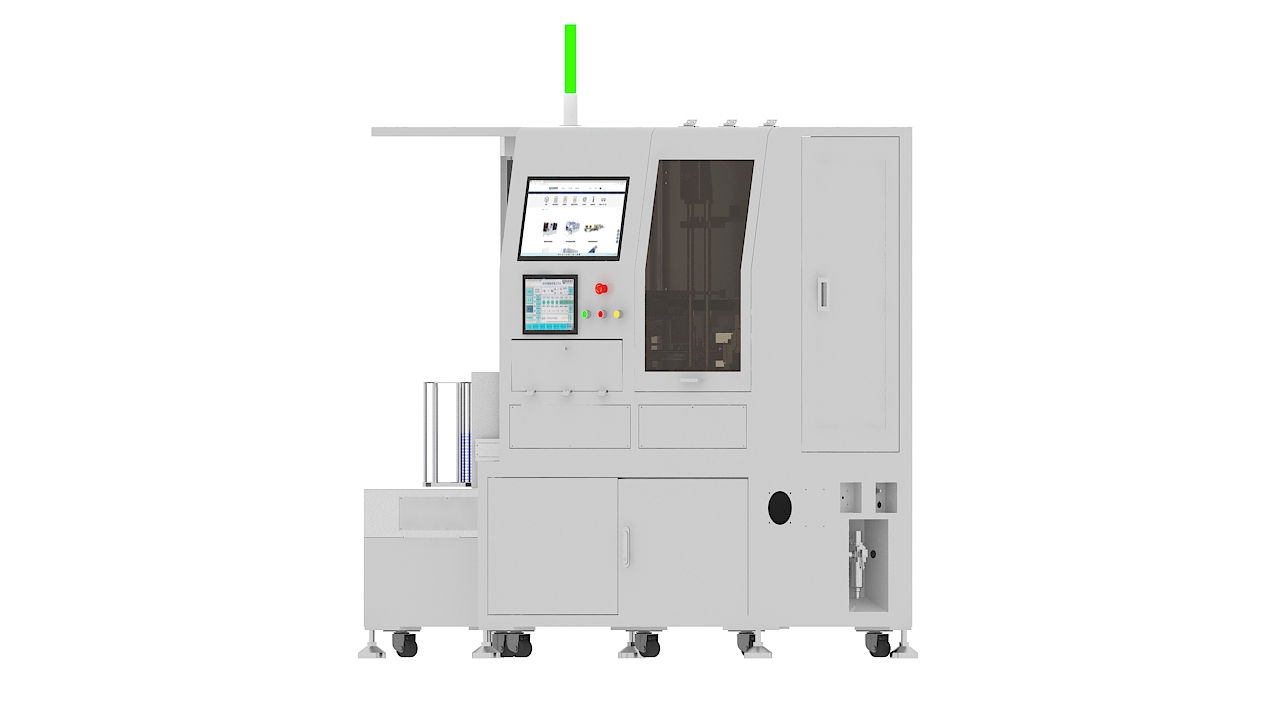

For the particularity of components, Future Att provides a SMD REEL automatic divide packager, which is fully automatic vacuum packaging, reduces risks such as static electricity, discharge, and moisture, and avoids damage during transportation and assembly.

Production Planning Material Management

Ensure production schedules are aligned with material availability. Coordinate with suppliers to ensure timely delivery of components and other materials to avoid production delays.

Traceability

Future Att will provide a SMD electronic tray automatic labeling machine to collect information for suppliers' incoming materials, input and bind them, so as to generate unique code labels, and automatically attach labels to materials to provide data support for quality traceability.

Feeder settings

Cross-reference the feeder settings with the bill of materials to ensure proper placement. Accurately configure feeders for components on placement machines.

Solder paste printing

Accurate solder paste deposition is achieved through an automatic stencil printer to ensure that the solder paste is accurately applied to the PCB.

Assembly Verification

Automated Optical Inspection (AOI) and In-Circuit Test (ICT) to verify correct component placement and solder joints.

Defect analysis

Enables continuous improvement by collecting data on recurring issues and analyzing it to determine root cause.

Waste management

It requires us to properly dispose of unused parts, expired materials, and any waste generated during assembly in an environmentally responsible manner.

Effectively manage the materials in the SMT production process through the whole process, improve the production efficiency of the production line, and ensure product quality and reliability.