Automatic labelling machine solution

Automatic code-sweeping, labelling, double-checking and discharging

-

Intelligent operation

Automatic scanning, labelling, double-checking and discharging throughout the process;

Intelligent operation

Automatic scanning, labelling, double-checking and discharging throughout the process;

-

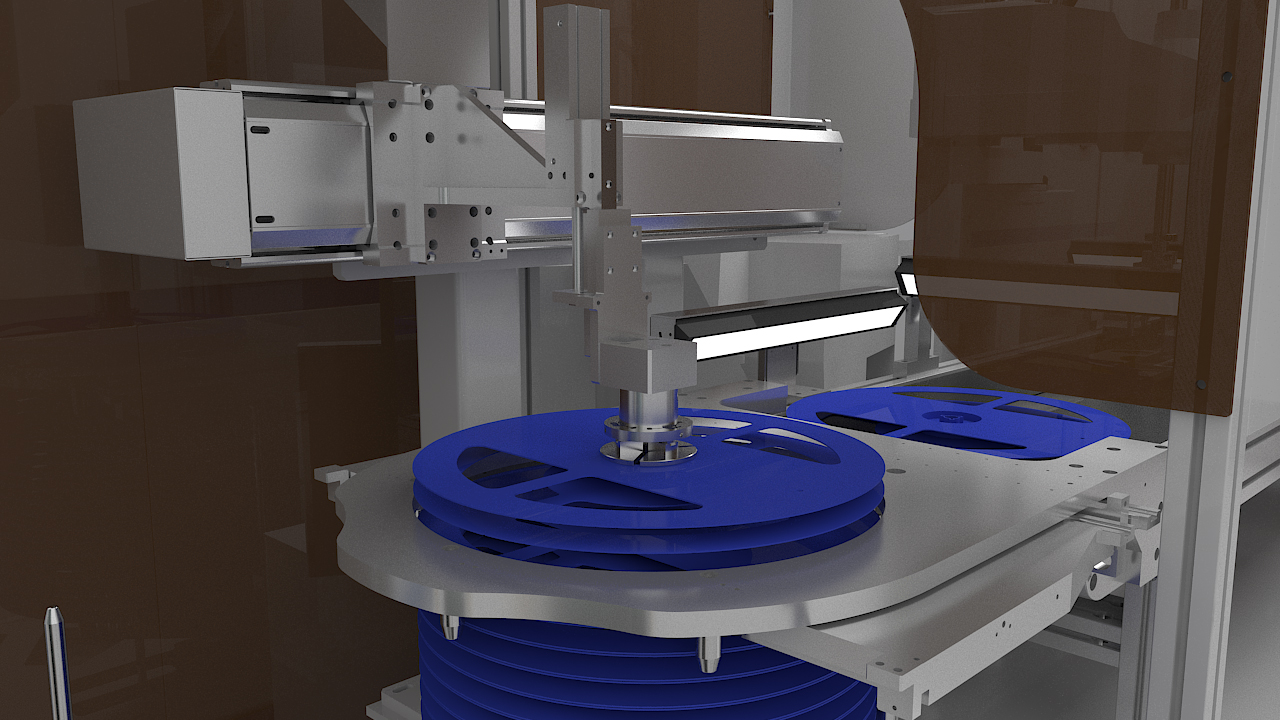

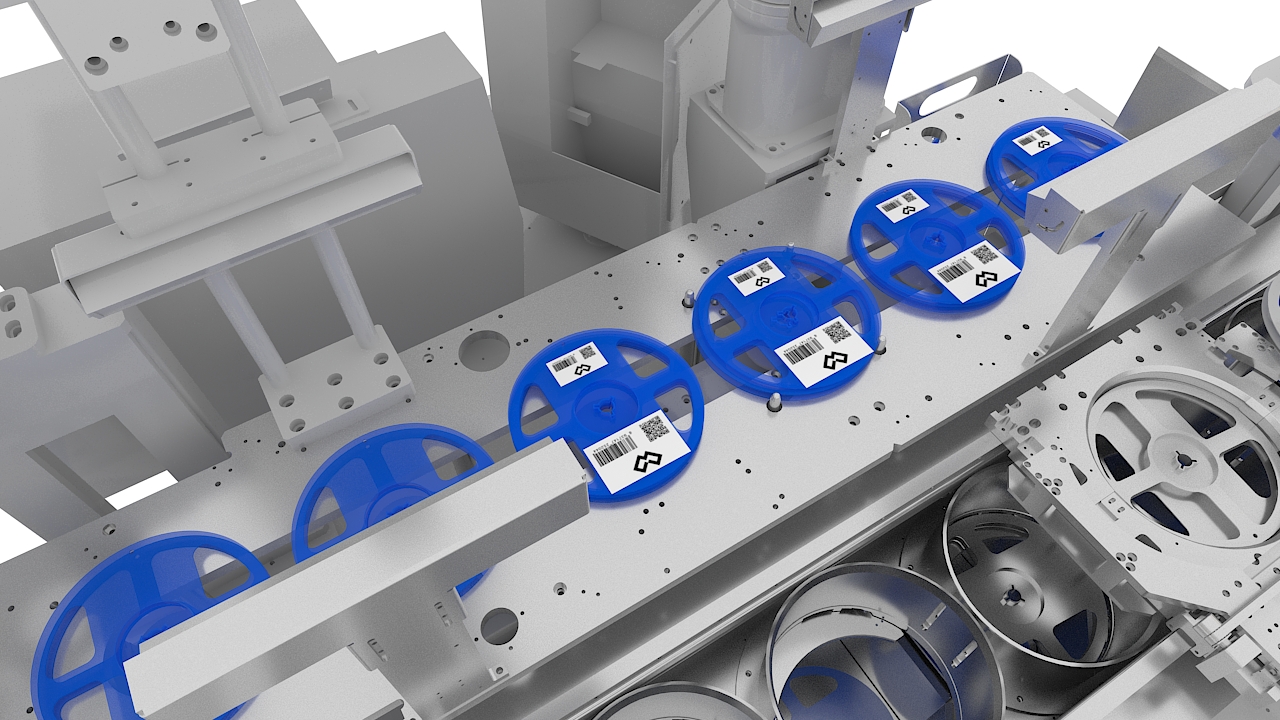

2、Automatic loadingThe loading jacks lift the trays and the jaws carry the trays to the fork conveyor line;

2、Automatic loadingThe loading jacks lift the trays and the jaws carry the trays to the fork conveyor line; -

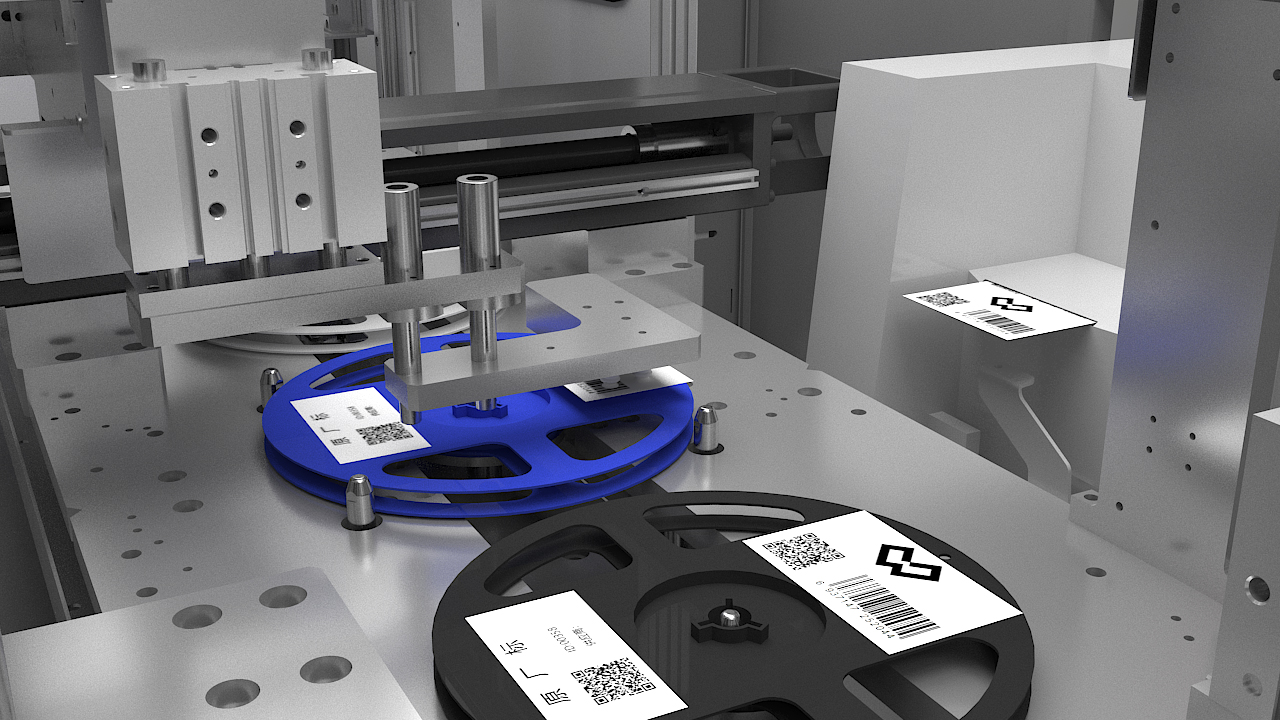

3、Automatic code readingThe industrial camera locates and reads the pallet and sends it to the WMS system;

3、Automatic code readingThe industrial camera locates and reads the pallet and sends it to the WMS system;

-

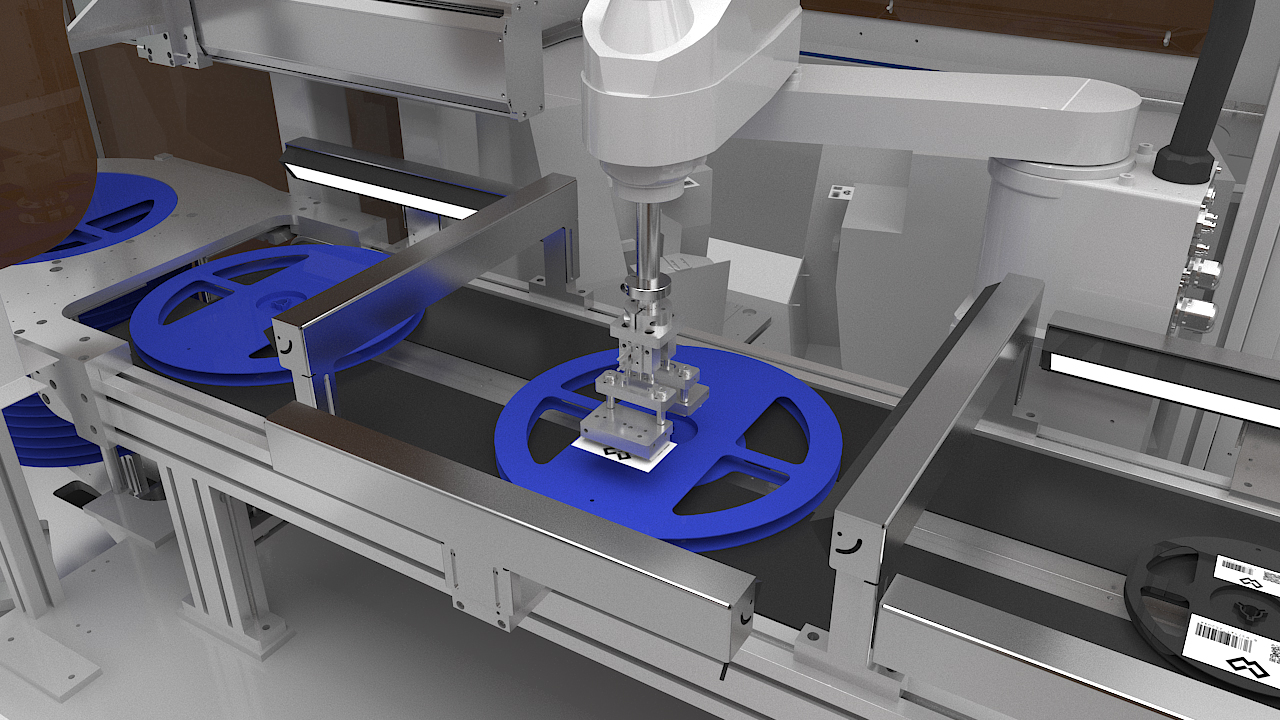

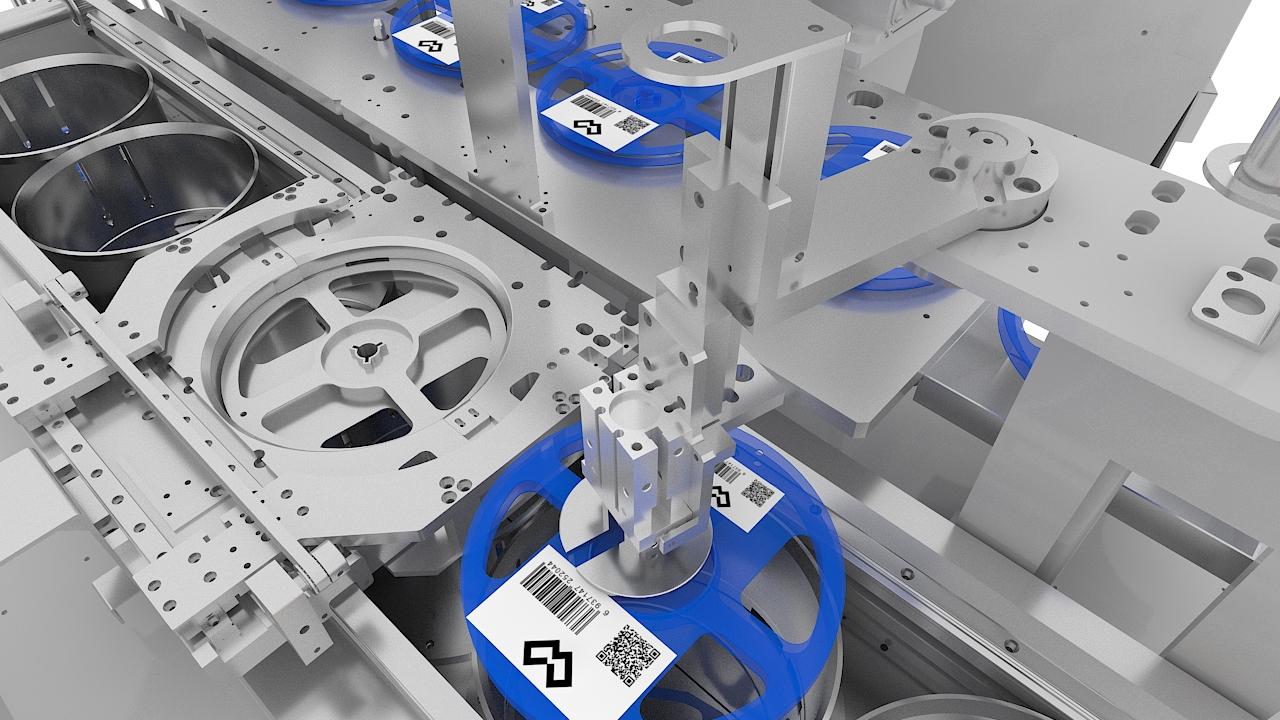

4、Automatic labelingThe material tray is transported to the labeling station and labeled automatically; labelling;

4、Automatic labelingThe material tray is transported to the labeling station and labeled automatically; labelling; -

5、Automatic reviewThe industrial camera carries out the review, and the result is sent to the WMS; conveyor will transport the material tray to the lower material station,

5、Automatic reviewThe industrial camera carries out the review, and the result is sent to the WMS; conveyor will transport the material tray to the lower material station, -

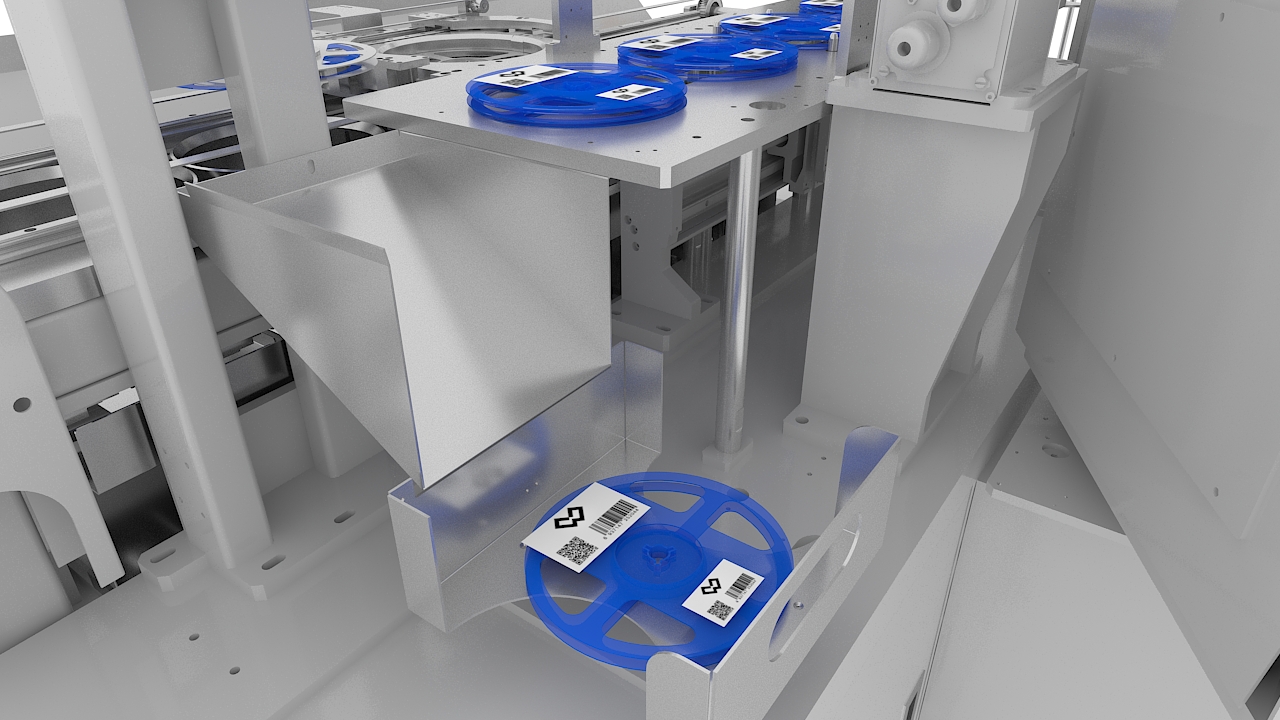

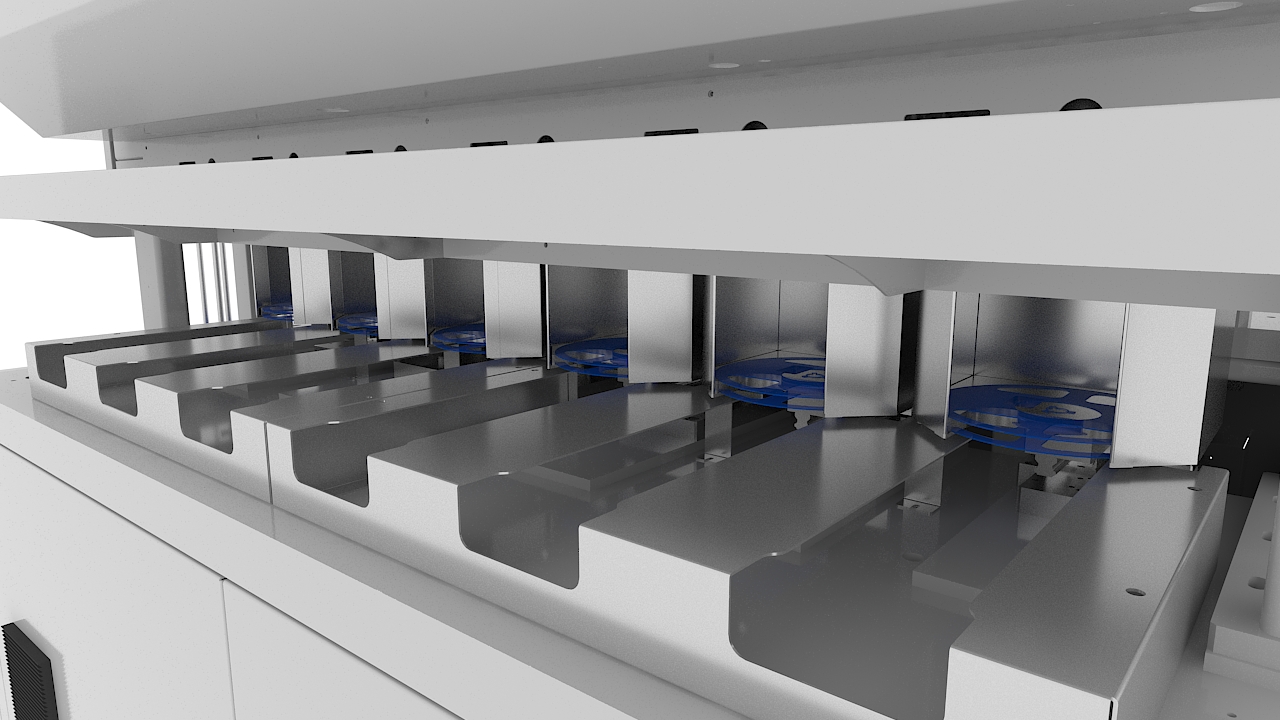

6、Automatic material dischargingAutomatic unloading, transported from the cache bin by an AGV trolley; warehouse/production line;

6、Automatic material dischargingAutomatic unloading, transported from the cache bin by an AGV trolley; warehouse/production line;

Functional features

l for 7" pallets

l system can be interfaced with any WMS, ERP, MES, etc.

l has high efficiency and stable performance

l automatically sweeps, labels, checks and discharges the material.

l is equipped with two 1000w pixel industrial cameras for code reading and review, with NG channels to meet the demand of accuracy rate

l is equipped with safety light curtain protection to ensure safety

Fully automatic labelling machine, the whole process of automatic operation, to meet the needs of customer orders, improve the production line production efficiency, and accurate and efficient, good stability, greatly reduce labour costs, to achieve quality, efficiency double upgrade.

|

|

Scope of application

Fully automatic labelling of electronic components (resistive original 7" SMD reels). Can be used by original manufacturers and distributors.

| Parameters | Automatic labeling machine |

|

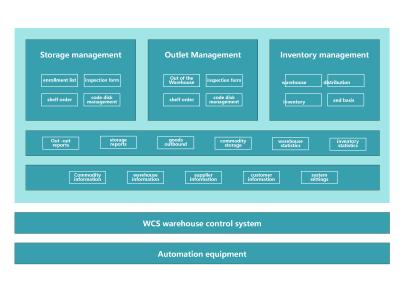

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

240 reels/loading; 60 reels/unloading |

| Efficiency | 1.8s/reel |

| Configuration | 2 sets of 1000w pixel industrial cameras (reading code + verification) |

| Sorting | Discharge in order, with an NG channel |

| Power Supply | AC220V(16A) |

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to local actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

2200*1300*1850 |

| Operation | Suggested for 1 person |

| Other | Configured with safety light curtains to protect personnel's safety and comply with EU safety standards. |