X-Ray Intelligent Counting Solutions

Accurate and efficient solution to the material "inventory" problem

-

2、Automatic loadingGripper jaws carry the trays to the conveyor line;

2、Automatic loadingGripper jaws carry the trays to the conveyor line; -

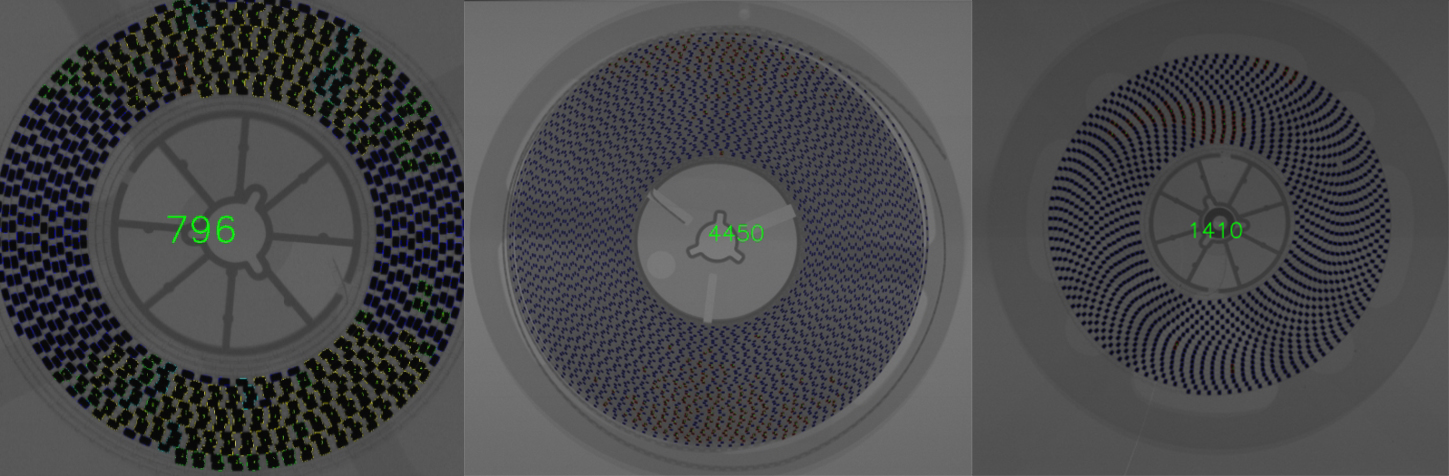

3、Automatic material countingFeeding of the trays into the x-ray counting area for automatic counting;

3、Automatic material countingFeeding of the trays into the x-ray counting area for automatic counting;

-

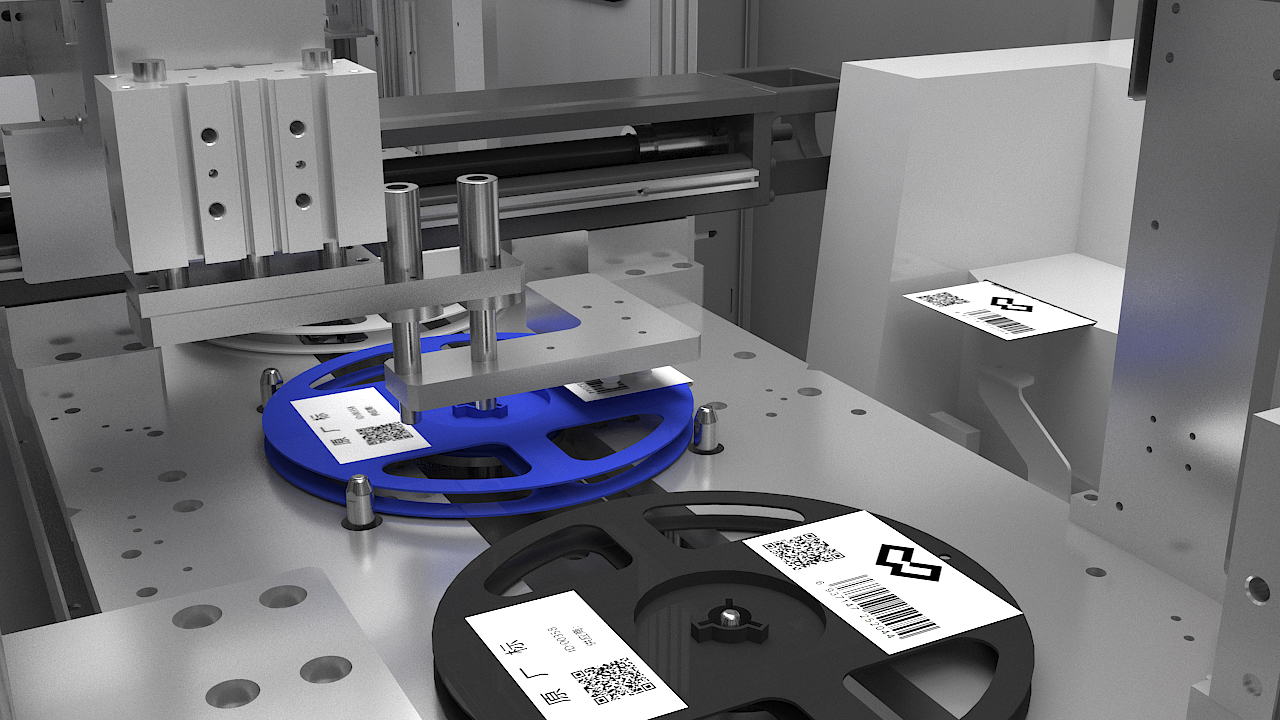

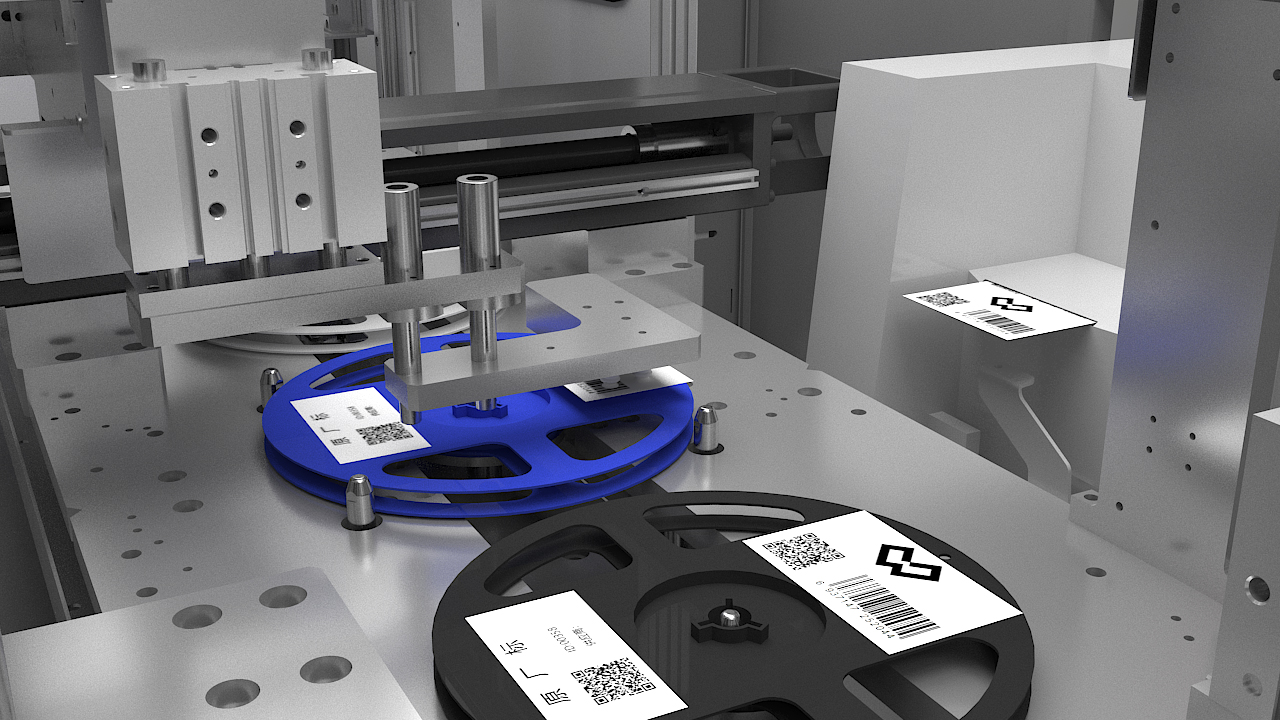

4、 Automatic labelingthen automatically conveyed to the labelling Printing of customer labels and automatic labelling;

4、 Automatic labelingthen automatically conveyed to the labelling Printing of customer labels and automatic labelling; -

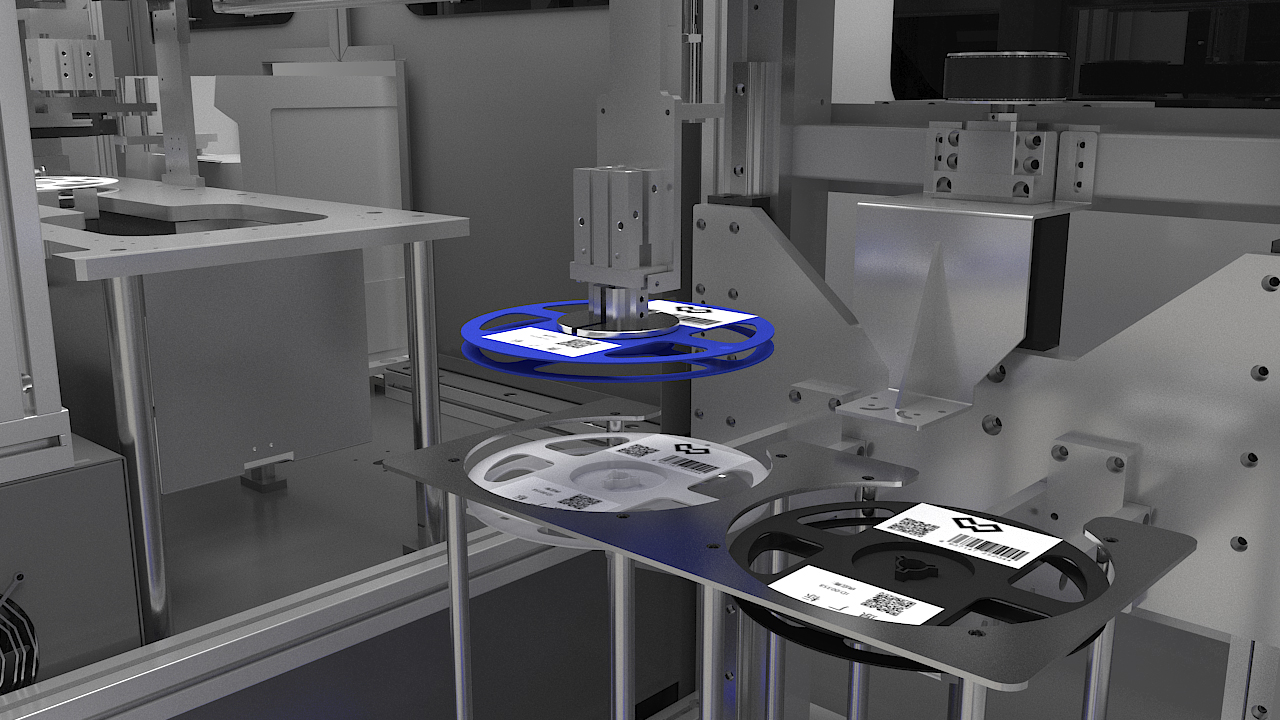

5、Automatic reviewIf the result of the review is unqualified, it is If If it passes, it is sent to the downcomer; if it does not pass, it is rejected to the NG port; review, the fork conveyor will transport the material tray to the lower material station,

5、Automatic reviewIf the result of the review is unqualified, it is If If it passes, it is sent to the downcomer; if it does not pass, it is rejected to the NG port; review, the fork conveyor will transport the material tray to the lower material station, -

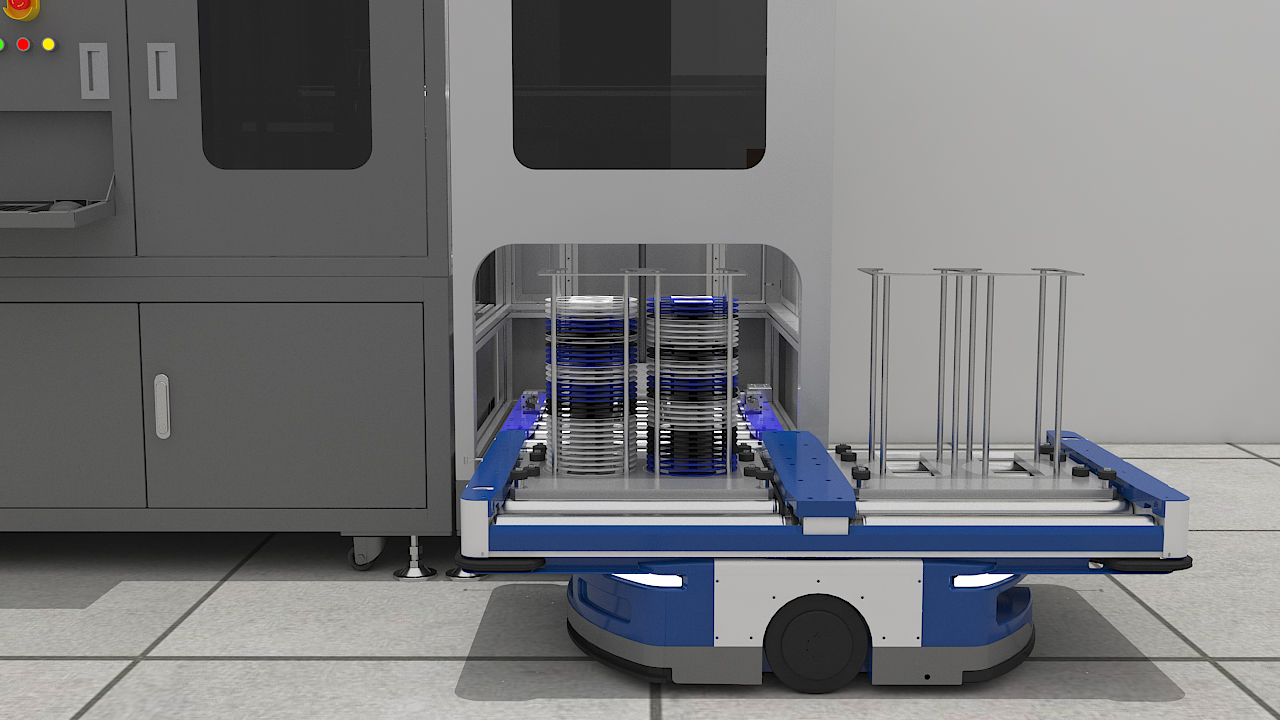

6、Automatic feedingAutomatic unloading, transported from the cache bin by an AGV trolley; warehouse/production line;

6、Automatic feedingAutomatic unloading, transported from the cache bin by an AGV trolley; warehouse/production line;

Functional features

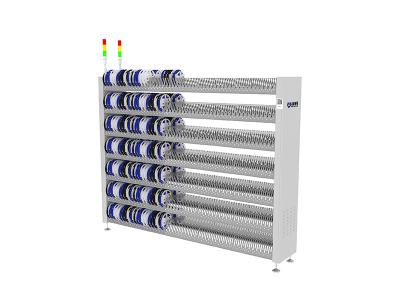

l supports 7-15" material, height 8mm-70mm

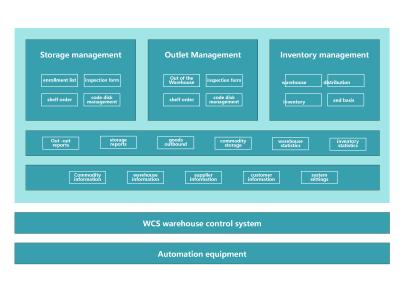

l system can be interfaced with any WMS, ERP, MES, etc.

l supports mixed loading mode, 2 trays can be placed on 7" and 1 tray on 13

l is fully compatible with online ordering and can be connected to a printer to support offline printing

l can count materials with 99.99% accuracy to ensure the accuracy of the material back to the end of the warehouse, lean management of material use and loss.

l is easy to operate and can be operated by 1 person.

Scope of application

Automatic storage and dosing of a wide range of electronic components for the SMT industry (compatible with 7 to 13 inch pallets)

| Parameters | X-ray SMT component counter (fully-automatic) |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

Diameter:7-15or materials of the same size in a flat state; Height:5mm~70mm |

| Efficiency | 780 reels/hour (mixed loading mode) |

| Accuracy | 99.99% (MIN detectable 01005) |

|

X-ray

configuration

|

17” flat panel detector with 139μm; VJ source 80KV/100W |

| Power Supply | AC220V(10A) |

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to the actual local power supply voltage) |

|

Dimensions

(L*W*H mm)

|

4330*1320*2050 |

|

Loading and

Unloading

|

120 reels loading buffer; 120 reels unloading buffe |

|

Series

Configurations

|

Automatic security access gate; Radiation dose: better than the national standard ≤1uSv/hr |

| Other | Compatible with online material point function, can also be connected to a printer, built-in 1000W industrial camera, offline labeling to prevent errors. |