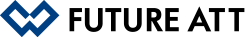

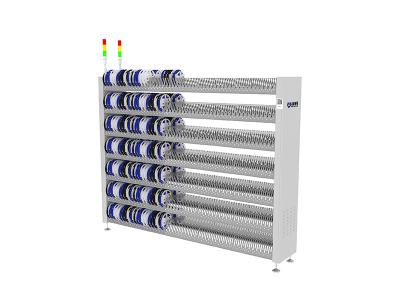

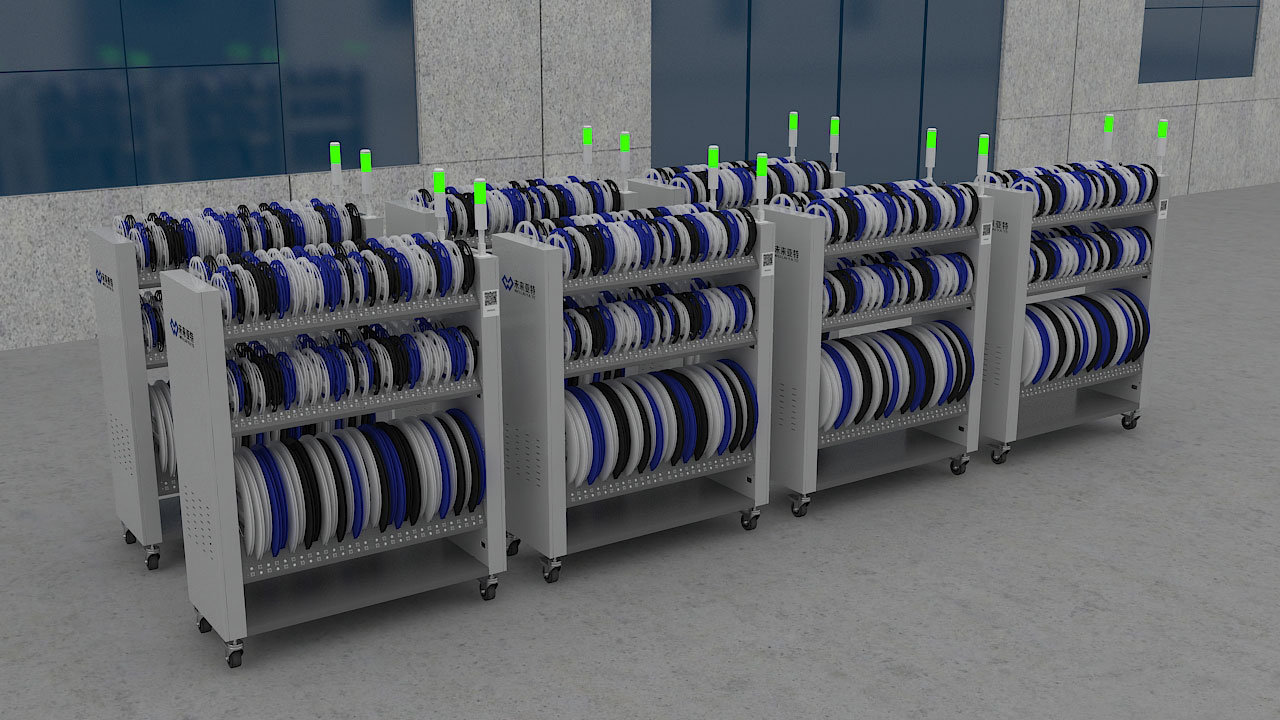

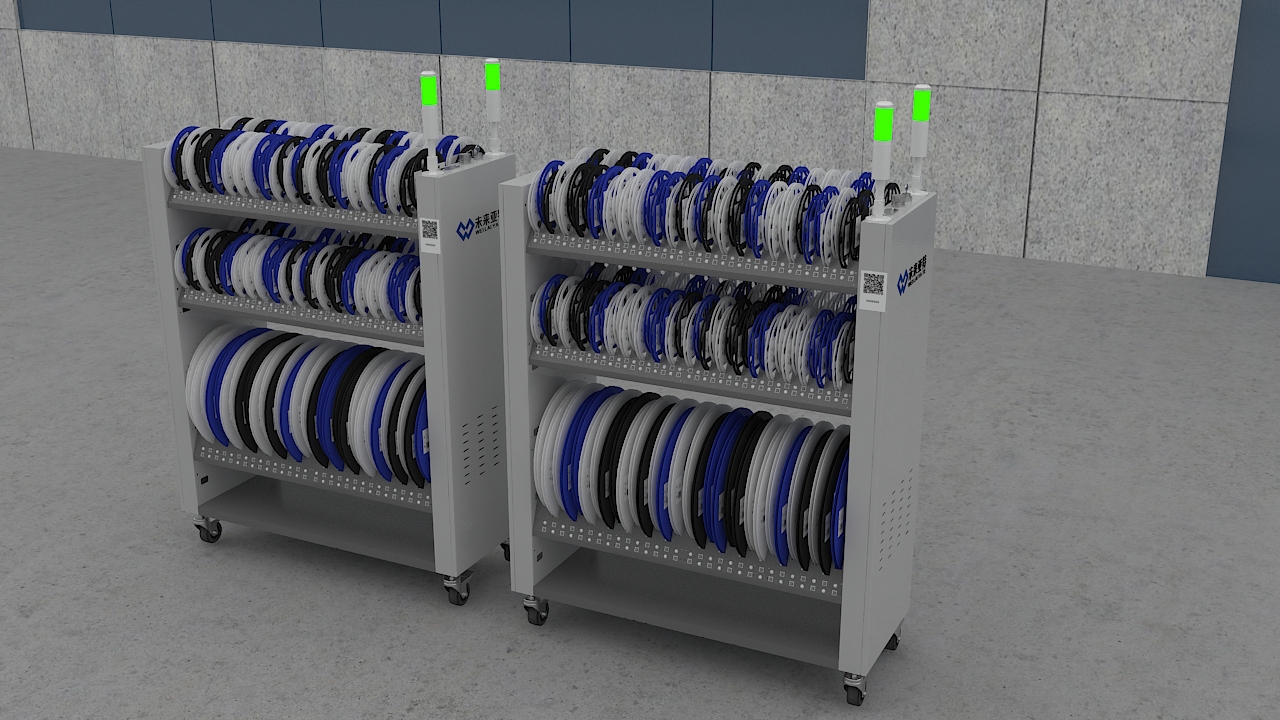

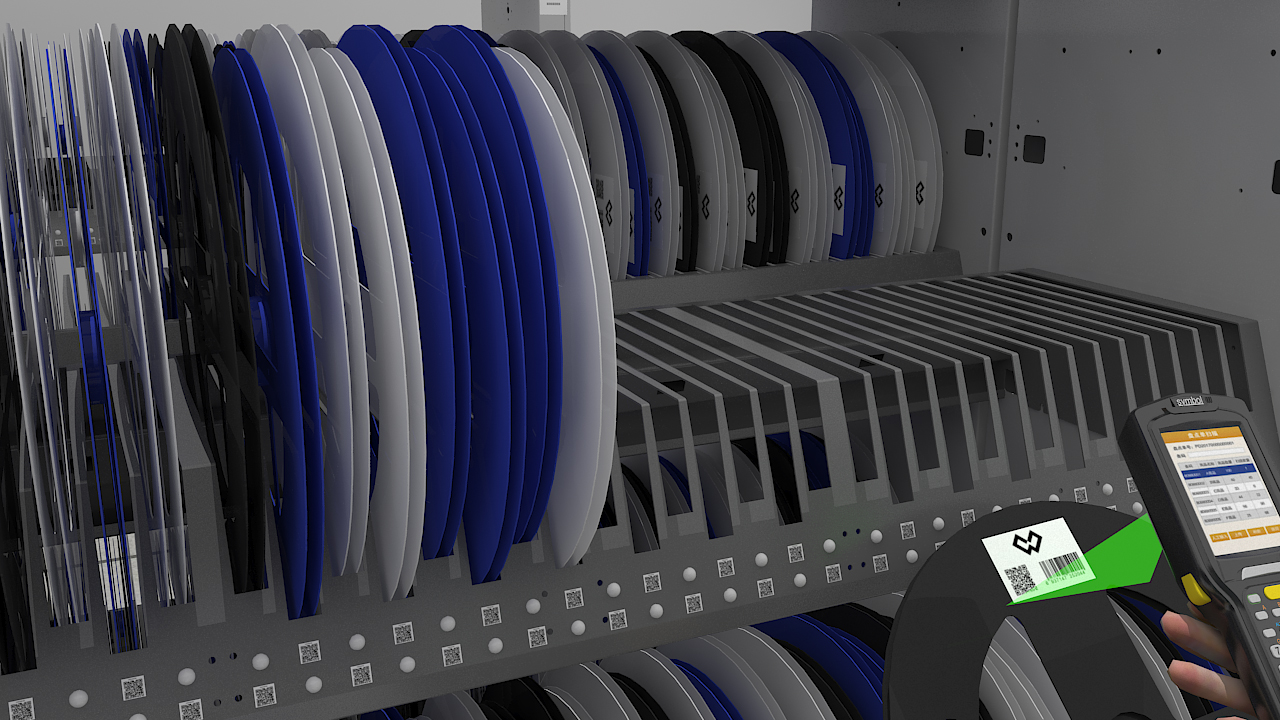

Intelligent electronic shelf solution

Fast receipt, dispatch and retrieval of materials

-

First in, first out

Information management, 5 times more efficient dispatching, fully automatic screening, no manual intervention

First in, first out

Information management, 5 times more efficient dispatching, fully automatic screening, no manual intervention

-

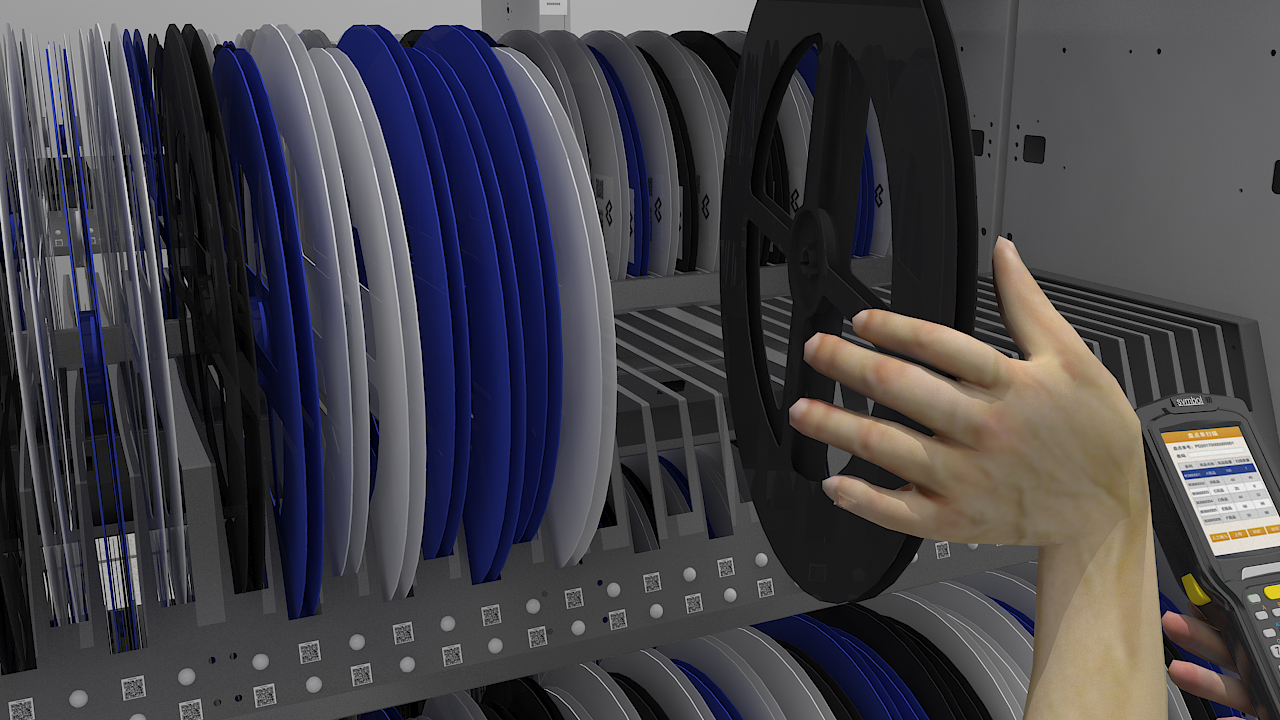

1、Storage of materialsNo need to choose a location when storing materials, just put the material tray into the empty space;

1、Storage of materialsNo need to choose a location when storing materials, just put the material tray into the empty space; -

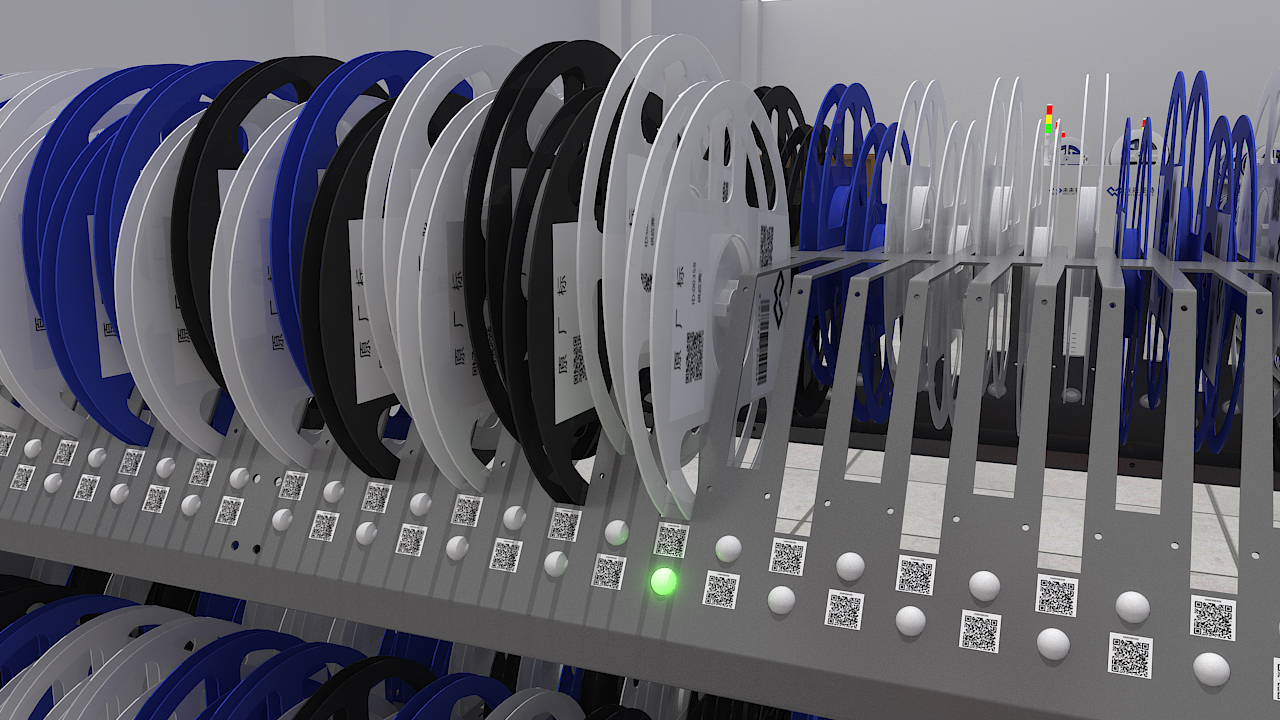

2、Upload systemThe sensor detects the material and uploads the information to the system, indicating that the material is successfully stored;

2、Upload systemThe sensor detects the material and uploads the information to the system, indicating that the material is successfully stored; -

3、Lighting prompt to pick up materialsWhen picking up materials, according to the system prompts to find the corresponding material rack;

3、Lighting prompt to pick up materialsWhen picking up materials, according to the system prompts to find the corresponding material rack;

-

4、Fetching materialThe light below the material to be picked up position lights up, pick up the material;

4、Fetching materialThe light below the material to be picked up position lights up, pick up the material; -

5、Upload systemThe sensor detects the material and uploads it to the system, indicating that the material has been taken successfully;

5、Upload systemThe sensor detects the material and uploads it to the system, indicating that the material has been taken successfully; -

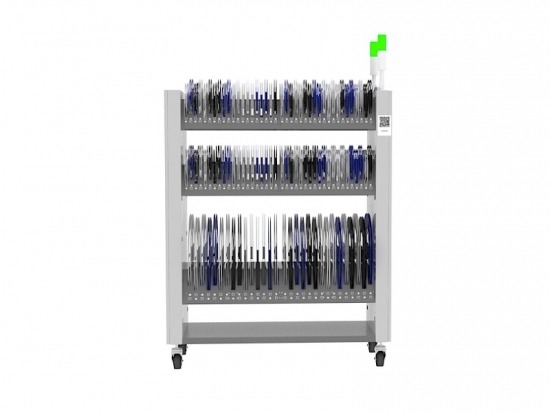

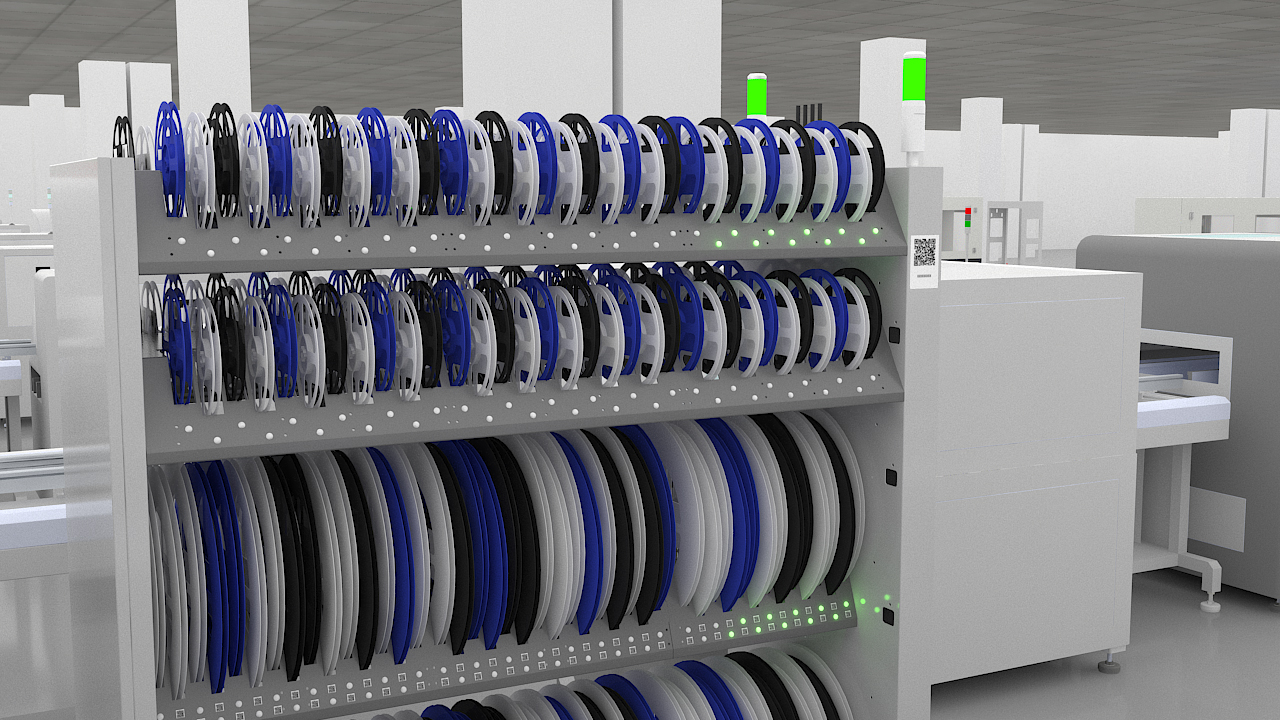

6、Docking to production lineSupport wired/wireless communication, convenient to push to the production line, improve production efficiency;

6、Docking to production lineSupport wired/wireless communication, convenient to push to the production line, improve production efficiency;

Functional features

l The system can be interfaced with any WMS, ERP, MES, etc.

l First-in, first-out, fully automatic material screening, no manual intervention, to achieve accurate management of materials

l Fast material picking according to lighted prompts, dummy-proof and error-proof, traceable data throughout

l Wired/wireless communication for easy interface to production

l High volumetric capacity, 2 times more storage capacity

l Intelligent operation, reducing labour and increasing work efficiency

l Easy to operate, 1 person equals 4 people

|

|

Scope of application

Used in the electronic components industry, mostly in SMT factories, for storage and dosing of electronic components (tray, bag and box are compatible), for storage in line side bins, for picking up materials, for taking materials according to the BOM, for taking materials in order according to the station table.

| Parameters | Mobile Intelligent material Rack |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

7~15”SMD;thickness 8mm~ 70mm, customizable |

|

Error prevention

mechanism

|

inductive/ QR code |

| Storage capacity | 80~200 units, customizable |

| Power Supply | AC220V(2A) |

|

Dimensions

(L*W*H mm)

|

1100*400*1200 |

| Other | Supports wired/wireless communi cationication |