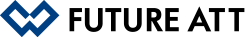

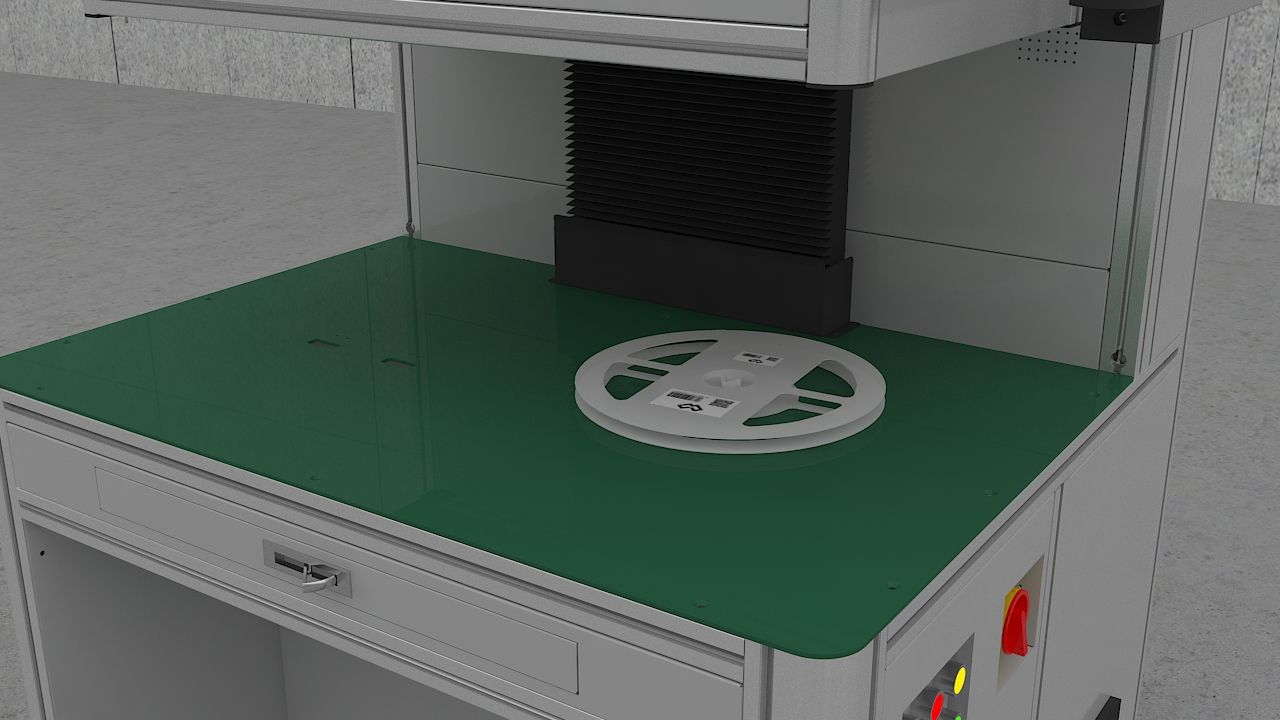

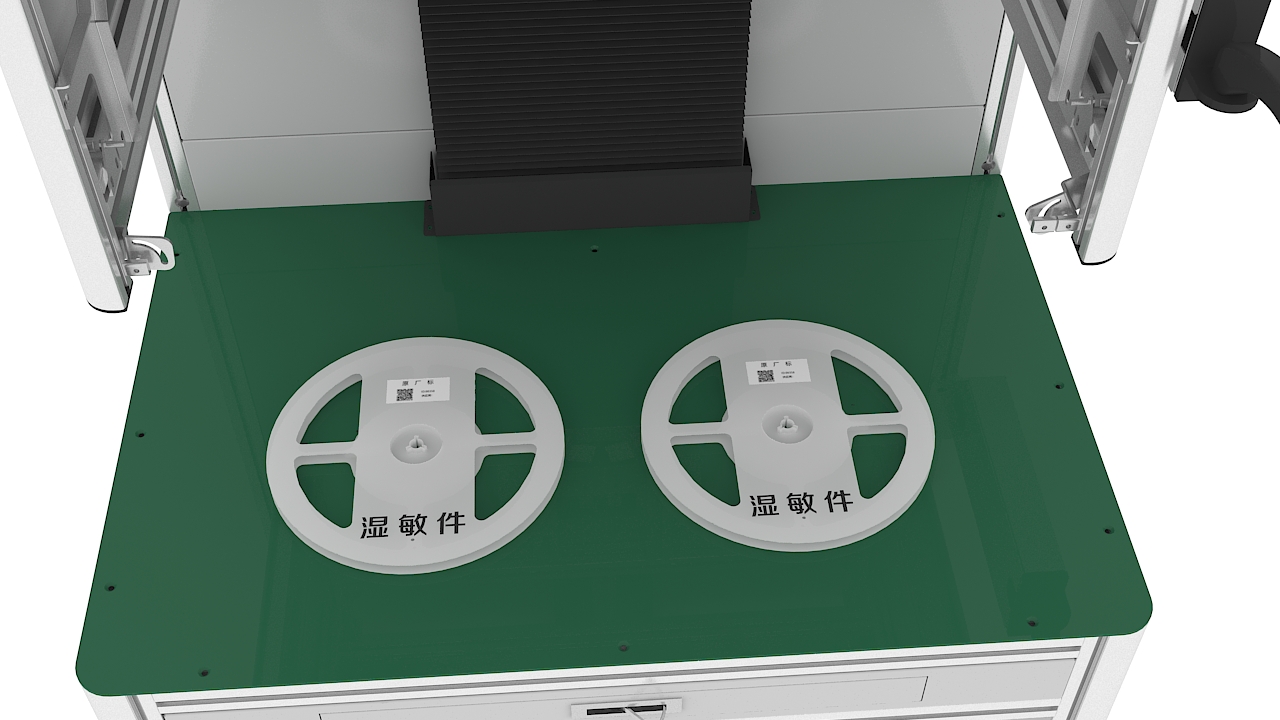

Semi-automatic labelling machine solutions

Automatic code reading, positioning and rechecking

-

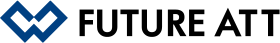

1、Manual loading, automatic code readingManual loading, adjustable camera height, automatic code reading, with prompting sound;

1、Manual loading, automatic code readingManual loading, adjustable camera height, automatic code reading, with prompting sound; -

2、Printing labels, labelingPrinter prints customer labels, operator does manual labelling; manually applies the label;

2、Printing labels, labelingPrinter prints customer labels, operator does manual labelling; manually applies the label; -

3、Automatic reviewPut the labeled material tray into the review station, automatic code reading, with a beep;

3、Automatic reviewPut the labeled material tray into the review station, automatic code reading, with a beep;

Functional features

l Suitable for 7" - 17" pallets

l The system can be interfaced with any WMS, ERP, MES, etc.

l Configuration of laser focus module, according to the height of the product, the laser automatically adjusts the height of the reading code imaging, large field of view, multi-position trigger

l Simple and easy to operate, only 1 person is needed

l 3.5~5s/pan, depending on manual operation proficiency

l Device support voice broadcast function, improve customer experience

l Equipped with two 2000w pixel industrial cameras for code reading and review to meet accuracy requirements

Machine vision uses infrared light source to hit the light (invisible light), relative to white light source, can avoid strong light to the operator eye stimulation, will not produce visual fatigue.

|

|

Scope of application

Suitable for automatic code reading and label data verification of electronic components (resistive components 7~17 inch SMD reels). Suitable for small batch shipments from distributors.

| Parameters | Vertical Ticket Printer (Dual-Station Single-Side) |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

diameter: 7”-17”, height: 10-300mm (with laser focusing module, automatically adapts to material height) |

| Efficiency | 3.5-5s/pcs (depending on the operator's proficiency) |

| Configuration | 2 sets of 2000w pixel industrial cameras (code reading + positioning + verification) |

| Power Supply | AC220V (10A) (overseas customers can customize according to the actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

960*1100*1980 |

| Other | Suitable for electronic component distributors and SMT factories for small-batch coding and labeling |