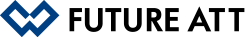

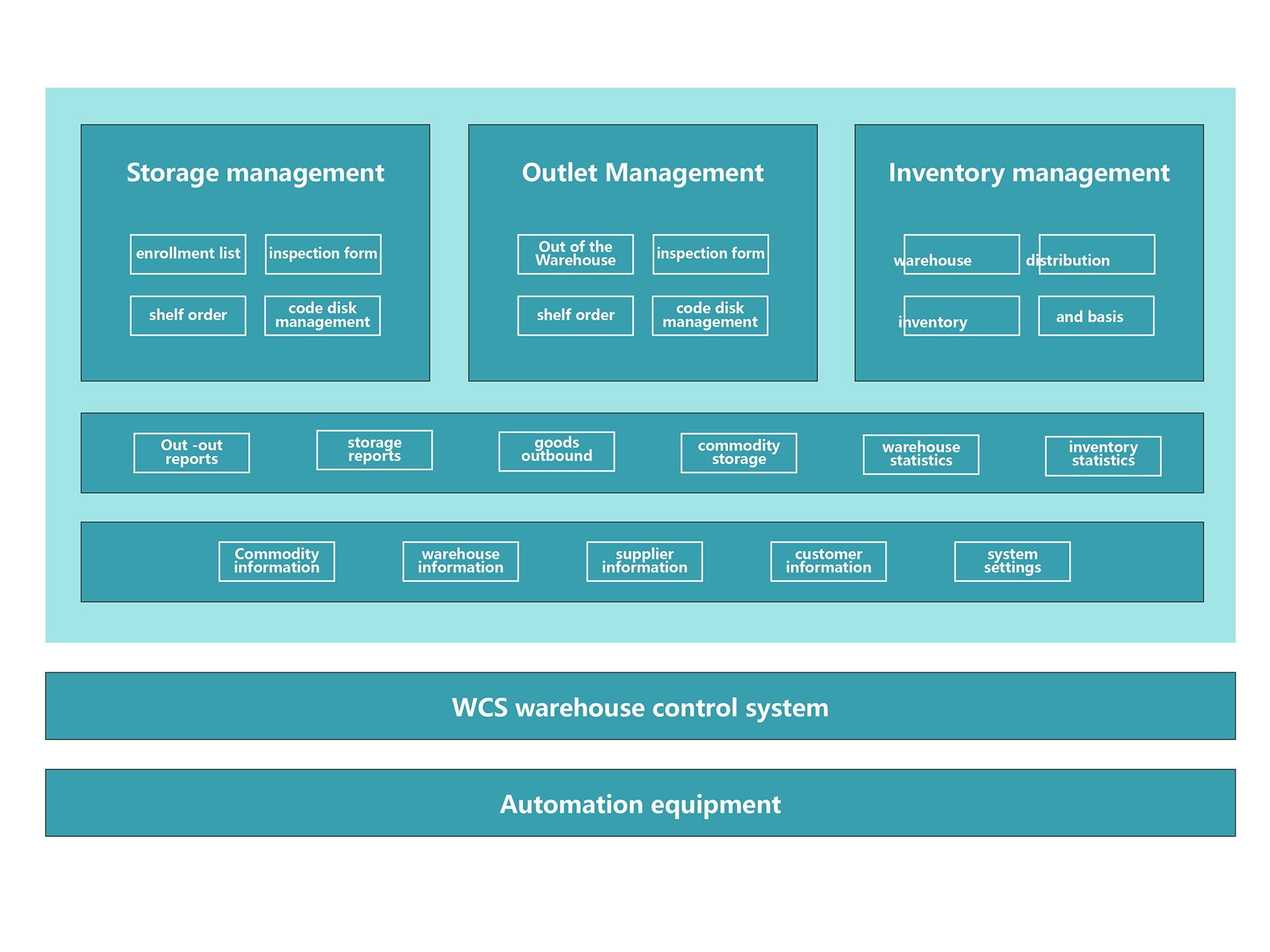

The WMS warehouse management system is a management system that effectively controls and tracks the entire process of logistics and cost management of warehouse operations through functions such as inbound operations, outbound operations, warehouse transfers, inventory transfers and virtual warehouse management, and the integrated use of batch management, material correspondence, inventory counting, quality control management, virtual warehouse management and immediate inventory management, to achieve or improve the enterprise's warehouse information management. The system can be used independently to perform inventory operations or in combination with other systems such as documents and vouchers to provide a more complete enterprise logistics management process and financial management information.

Advantages

l Better management of basic information - High utilisation of documents - Accurate inventory

l High operational efficiency

l Low inventory and high utilisation of material assets

l Existing operating procedures are less difficult to implement

l Easy to develop a sound maintenance plan

l Data on time, cost reduction

l Provides historical record analysis

l Timely delivery and correct use of documentation following changes to procedures

l Improved efficiency in the reconciliation of warehouse and financial workload

l Strict budget control and reduced returns

Function modules

System function setting module

Customised management rules for the entire system, including the ability to define administrators and their operating passwords.

Basic information maintenance module

Each batch of products generates a unique basic barcode serial number label, users can define the serial number according to their needs, each model of product has fixed coding rules, in the database can be added, deleted and edited.

Purchase Management Module

(1) Purchase order: When a purchase is required, a purchase order can be filled, which does not affect the inventory at this time.

(2) Purchase Receipt: When a purchase order is approved and the goods arrive after the purchase has been completed, the goods are first tagged with a barcode serial number and then the barcode is scanned on the purchase receipt, which is then saved and the stock is automatically increased.

(3) Other incoming goods: including the return of loaned goods, returns, etc. only need to fill in the purchase receipt.

Warehouse Management Module

(1) Product inbound: purchase inbound or other inbound, automatically generate the inbound order number, goods and can choose convenient and fast, - can distinguish between normal inbound, return inbound and other different inbound way.

(2) product out: sales out or other out, can automatically generate the out of the warehouse order number, can distinguish between the normal out of the warehouse, gifts out of the warehouse and other different ways.

(3) Inventory management: no need for manual management, when inbound and outbound, the system automatically generates the number of inventory of each product, easy to query.

(4) Special product library: when the customer needs to distinguish products, you can set up a virtual warehouse to manage the products that need to be distinguished, the functions and normal product library consistent.

(5) transfer management: for the need to transfer between different libraries, you can automatically generate the transfer order number, support the goods in different warehouses arbitrary transfer.

(6) Inventory management: users can take inventory of the warehouse at any time, automatically generate inventory documents, so that inventory work is convenient and fast.

(7) Stock limit alarm: When the stock quantity does not meet an amount, the system alarm.

Sales Management Module

Sales order: when the sales out of the warehouse, first fill out the sales out of the warehouse, at this time does not affect the inventory.

Sales order: when the sales are out of the warehouse, the serial number of the product will be scanned into the order, and after saving, the inventory report will be automatically reduced by this type of product.

Report Generation Module

Automatic generation of month-end, quarter-end and year-end sales, purchase and stocktaking reports, with user defined reports.

Enquiry functions

Purchase order queries, sales order queries, individual product queries, stock queries, etc. (user defined).

Queries are based on certain conditions: barcode serial number, date of dispatch, dispatch customer, etc.

History search function

History management for goods, staff and customers

This includes the history of goods in stock, staff and customers.