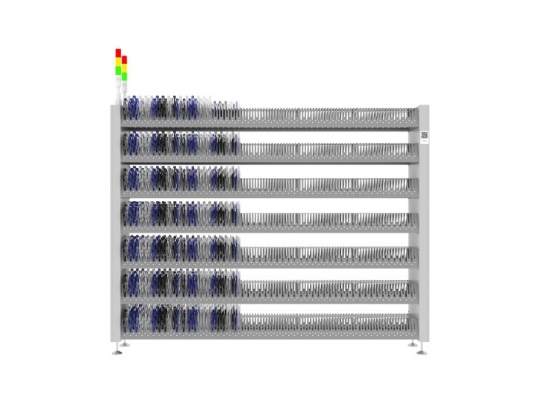

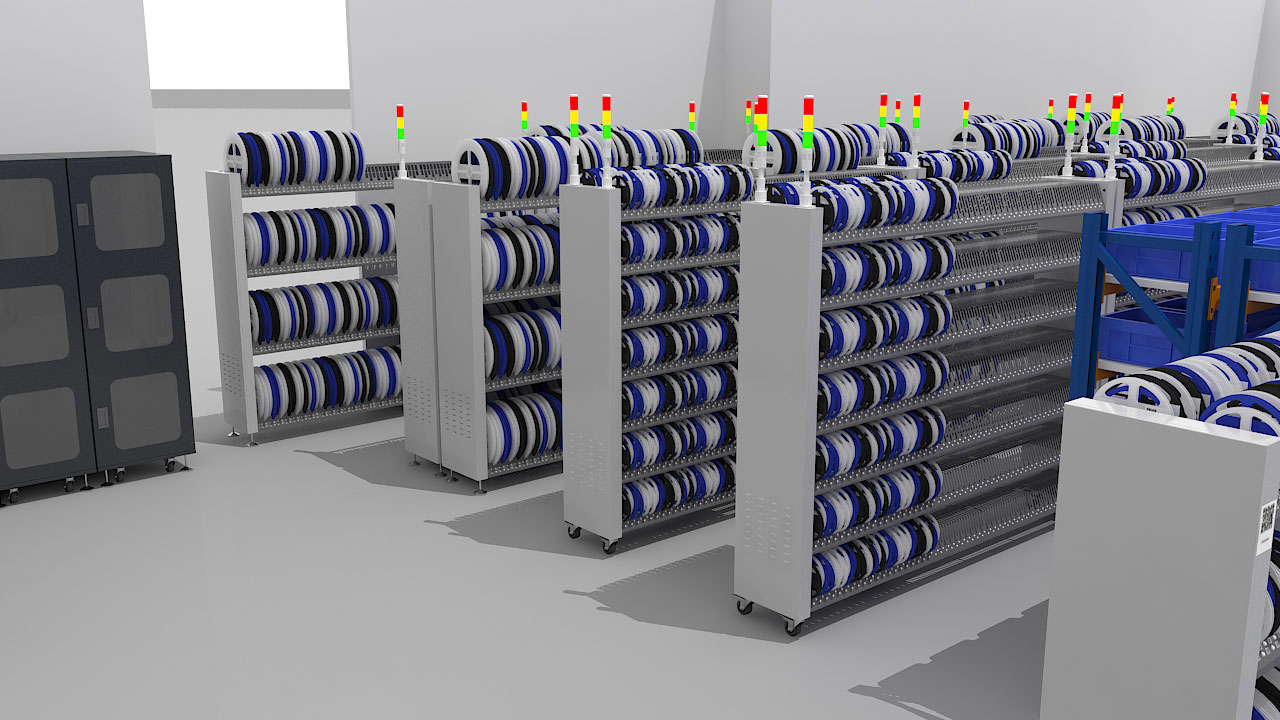

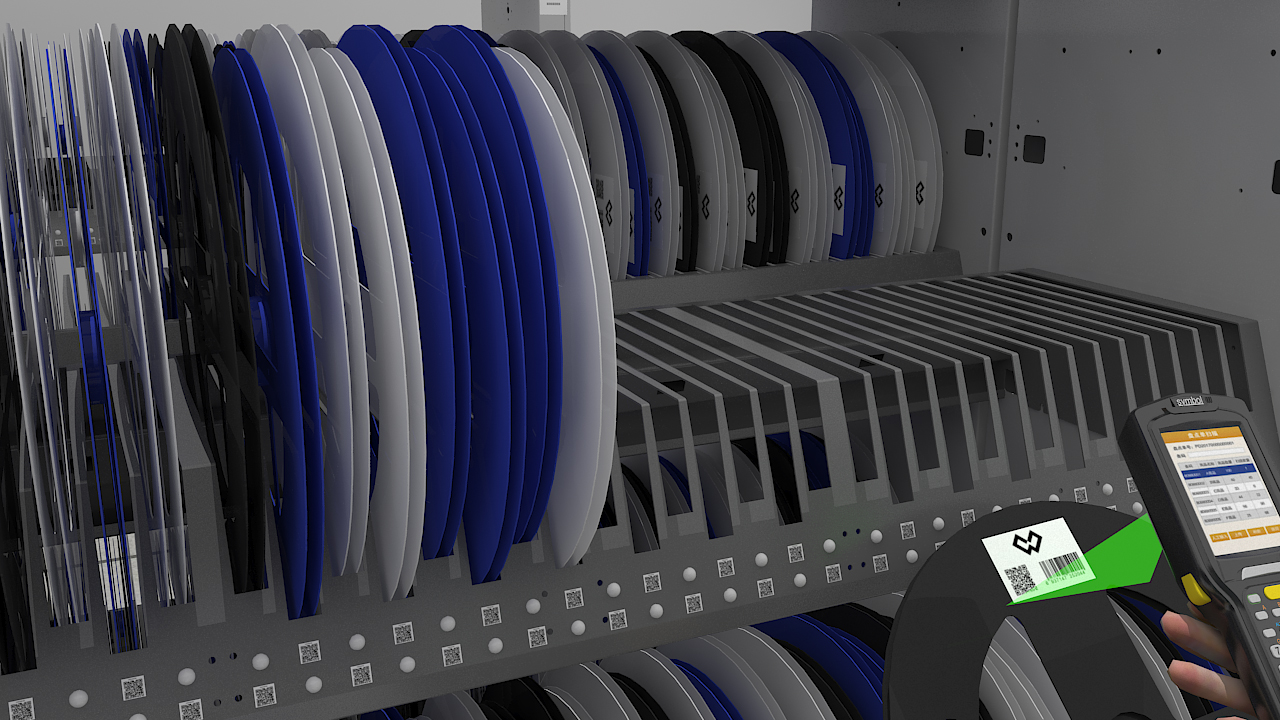

Intelligent electronic shelf solution

Fast receipt, dispatch and retrieval of materials

-

First-in, first-out

Information management, 5 times more efficient dispatching, fully automatic screening, no manual intervention

First-in, first-out

Information management, 5 times more efficient dispatching, fully automatic screening, no manual intervention

-

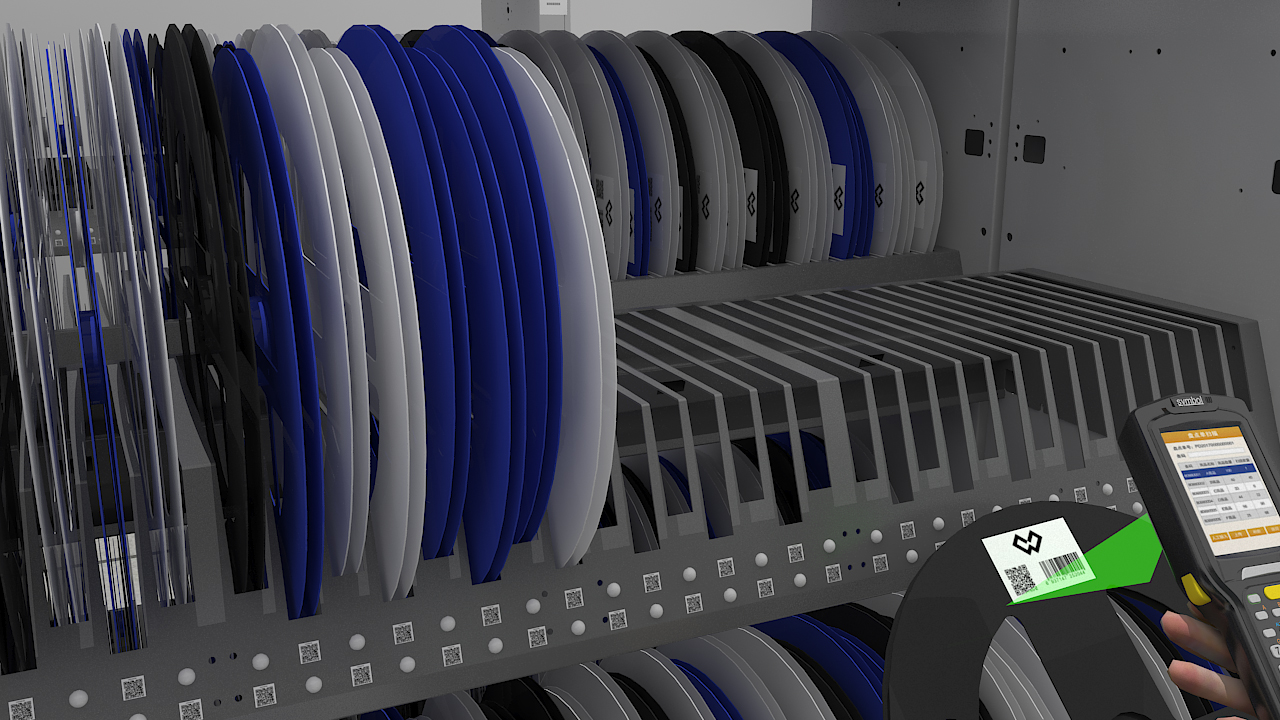

1、Storage of materialsNo need to choose a location when storing materials, just put the material tray into the empty space;

1、Storage of materialsNo need to choose a location when storing materials, just put the material tray into the empty space; -

2、Upload systemThe sensor detects the material and uploads it to the system, indicating successful storage;

2、Upload systemThe sensor detects the material and uploads it to the system, indicating successful storage; -

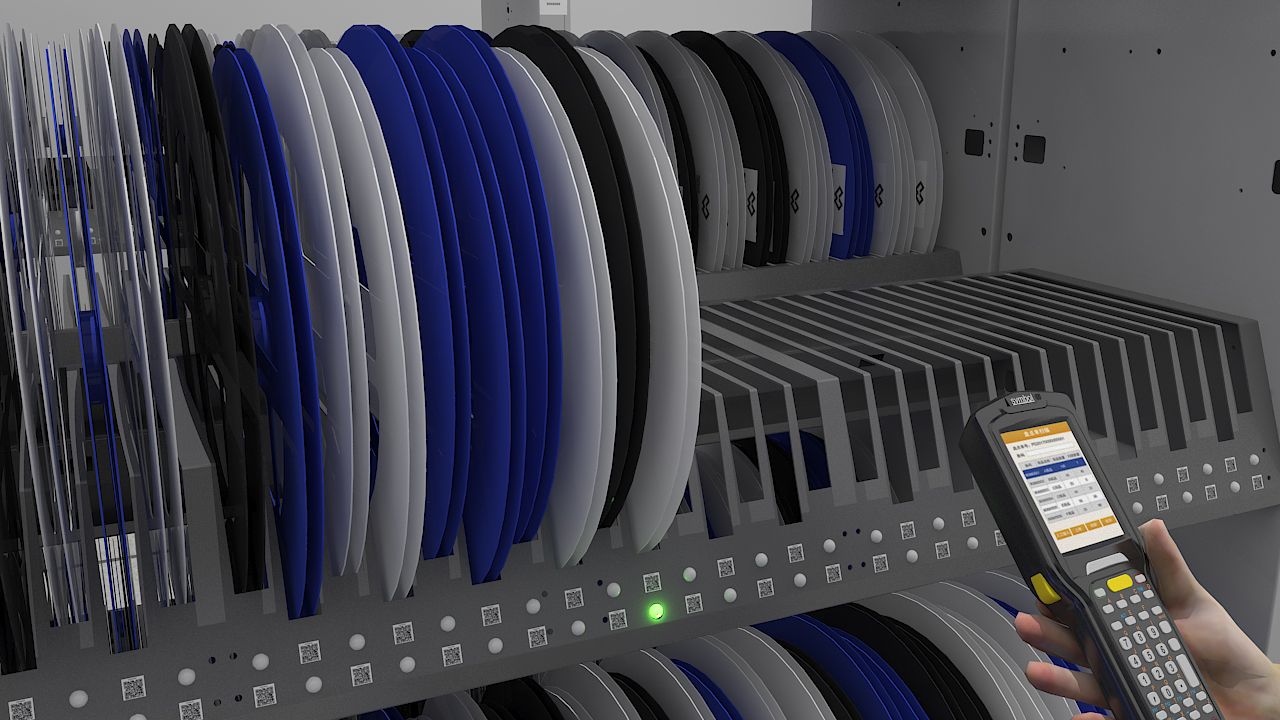

3、Lighting prompt to pick up materialsWhen picking up materials, according to the system prompts to find the corresponding material rack;

3、Lighting prompt to pick up materialsWhen picking up materials, according to the system prompts to find the corresponding material rack;

-

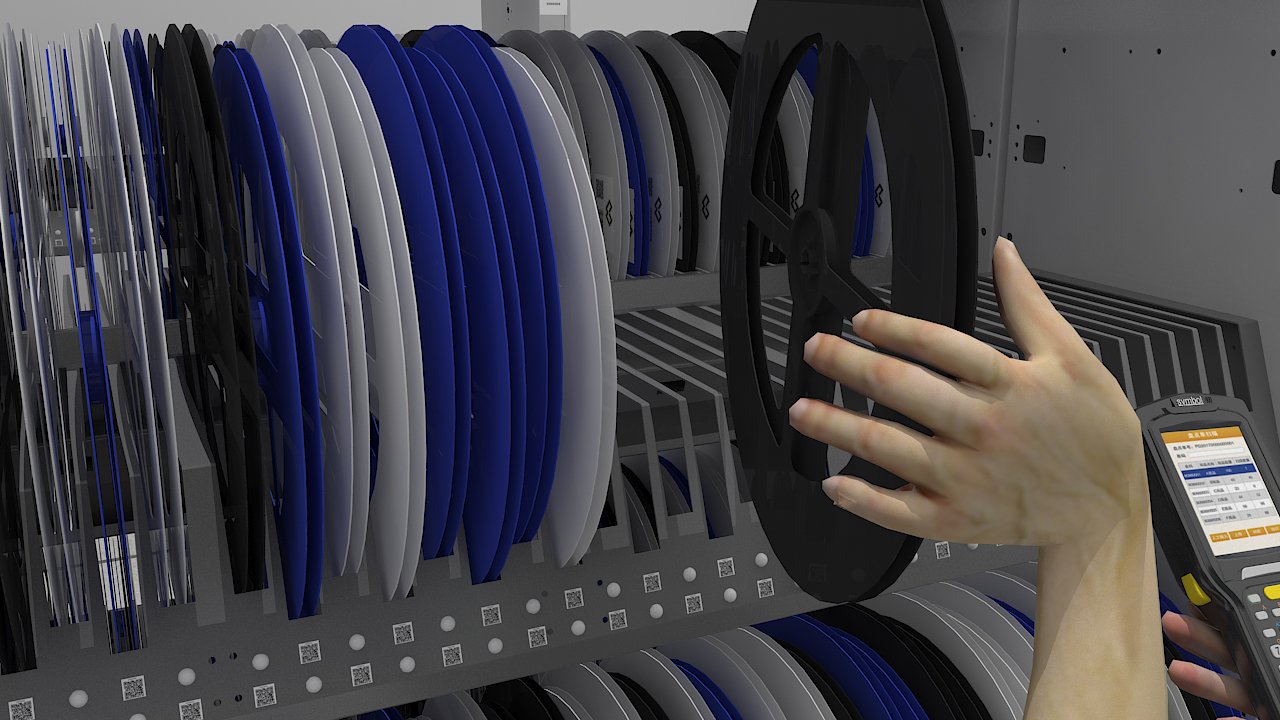

4、Fetching materialThe light below the material to be picked up position lights up, pick up the material;

4、Fetching materialThe light below the material to be picked up position lights up, pick up the material; -

5、Upload systemThe sensor detects the material and uploads it to the system, indicating successful pick-up;

5、Upload systemThe sensor detects the material and uploads it to the system, indicating successful pick-up; -

6、Cycle operationLoading and unloading according to customer requirements, cycle operation;

6、Cycle operationLoading and unloading according to customer requirements, cycle operation;

Functional features

l The system can be interfaced with any WMS, ERP, MES, etc.

l First-in, first-out, fully automatic material screening, no manual intervention, to achieve accurate management of materials

l Quick pick-up according to lighted prompts, dummy-proof and error-proof, traceable data throughout

l High volume rate, 2 times more storage capacity

l Intelligent operation, reducing labour and increasing efficiency

l Simple operation, 1 person equals 4 people

Inductive electronic material rack, high volume rate, improve space utilisation, material tray can be stored at will, the system automatically reminds the available storage space, the operator can operate according to the signal prompt, to achieve the first-in, first-out, fast material collection and retrieval, greatly enhance the operational efficiency, reduce labour costs, and simple operation.

|

|

Scope of application

Used in the electronic components industry, mostly in SMT factories, for storage and dosing of electronic components (tray, bag and box are compatible), for storage in line side bins, for picking up materials, for taking materials according to the BOM, for taking materials in order according to the station table.

| Parameters | Intelligent material storage Rack |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

7~15”SMD;thickness 8mm~ 70mm, customizable |

|

Error prevention

mechanism

|

inductive/ QR code |

| Storage capacity | Maximum of 1400/7 layers, with 200 on each layer. |

| Power Supply | AC220V(3A) |

|

Dimensions

(L*W*H mm)

|

2400*400*2000 |

| Other | Materials and colors can be customized, and the sensing materials can monitor the status of material entry and exit in real-time |