FUTUREATT

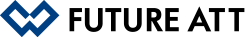

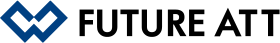

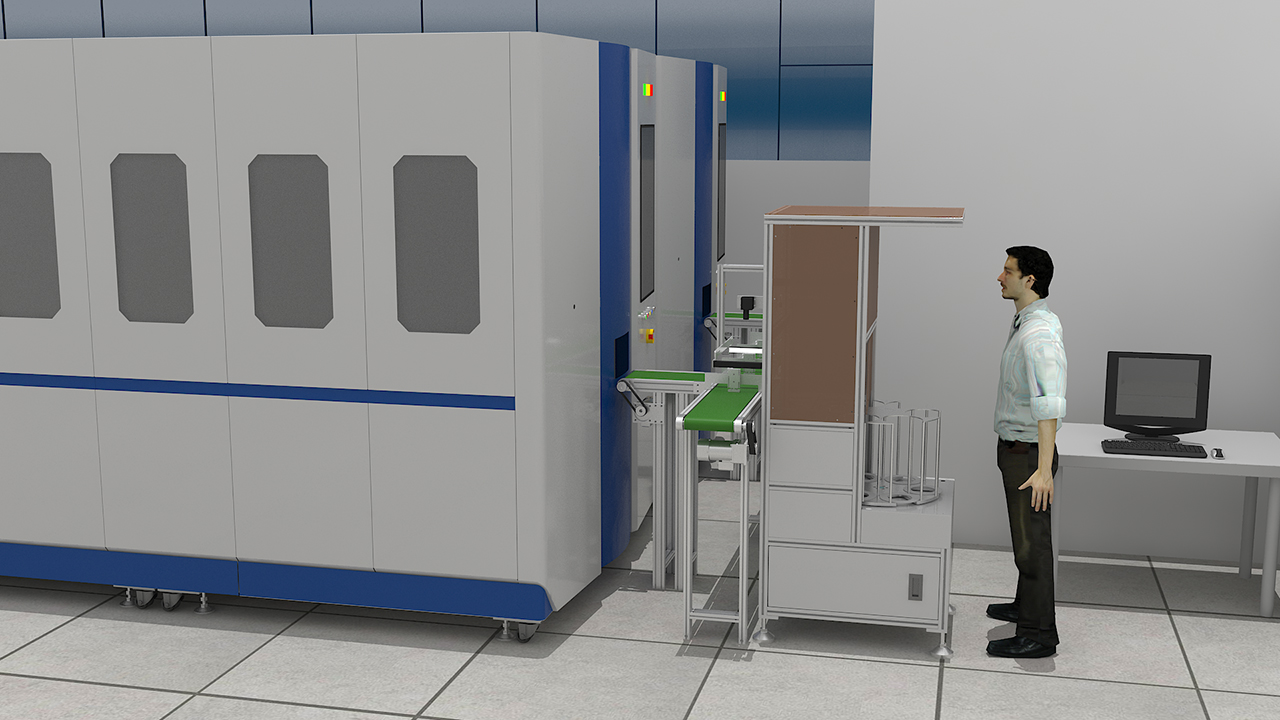

SMT INTELLIGENT AUTOMATIC WAREHOUSE

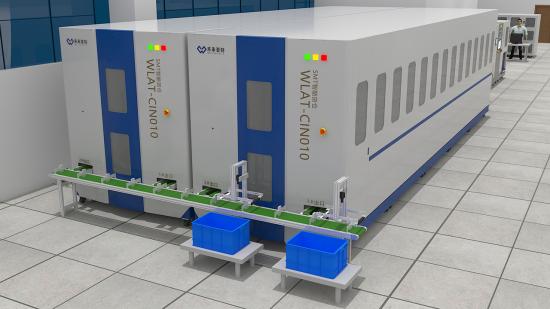

The whole process of automatic storage and automatic batching realizes precise management of materials, combined with material R-ID, it can automatically send orders to the tray, first in first out, and send materials according to quantity requirements; optional temperature and humidity management module can manage materials at constant temperature and humidity; according to System command, receiving BOM order automatic picking, dual-channel unloading. It can be docked with AGV picker + swing robot, and automatically send materials to the production line.

The whole process of automatic storage and automatic batching realizes precise management of materials, combined with material R-ID, it can automatically send orders to the tray, first in first out, and send materials according to quantity requirements; optional temperature and humidity management module can manage materials at constant temperature and humidity; according to System command, receiving BOM order automatic picking, dual-channel unloading. It can be docked with AGV picker + swing robot, and automatically send materials to the production line.

Reduce manual intervention, high efficiency

of automatic access

-

High Picking Efficiency• 7~8 times increase in picking efficiency• Improvement in storage capacityby 1.5x through enhanced space utilization

High Picking Efficiency• 7~8 times increase in picking efficiency• Improvement in storage capacityby 1.5x through enhanced space utilization -

High Precision• Precise material picking and highpositioning accuracy• Reduced manual intervention withaccuracy rate up to 100%

High Precision• Precise material picking and highpositioning accuracy• Reduced manual intervention withaccuracy rate up to 100%

-

Intelligent Management

• Full high-speed automatic accessthroughout the process• Adoption of First-in-First-out (FIFO)principle

Intelligent Management

• Full high-speed automatic accessthroughout the process• Adoption of First-in-First-out (FIFO)principle -

Unmanned Operation• 24-hour unmanned operation

Unmanned Operation• 24-hour unmanned operation -

Temperature and Humidity

Management Module• Materials can be managed with constant temperature and humidity.

Temperature and Humidity

Management Module• Materials can be managed with constant temperature and humidity.

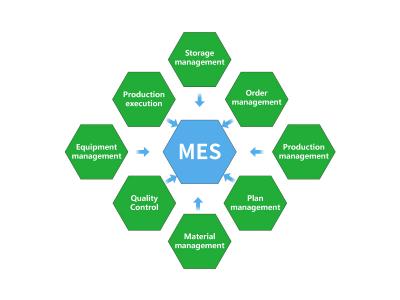

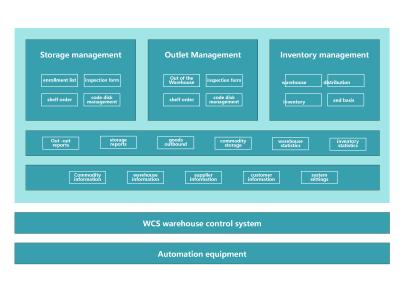

• The system can be connected with any WMS, ERP, MES, etc.

• R-ID generation can dispatch orders to disks, first in first out, to achieve accurate management of materials

• Equipped with a temperature and humidity management module, which can manage materials at a constant temperature and ensure the quality of materials

• Fool-proof and error-proof, the accuracy rate is 99.99%

• With unique code, materials are traceable

• Intelligent operation, reducing labor force and improving work efficiency

• Simple and easy to operate, only one person is required

|

Parameters

|

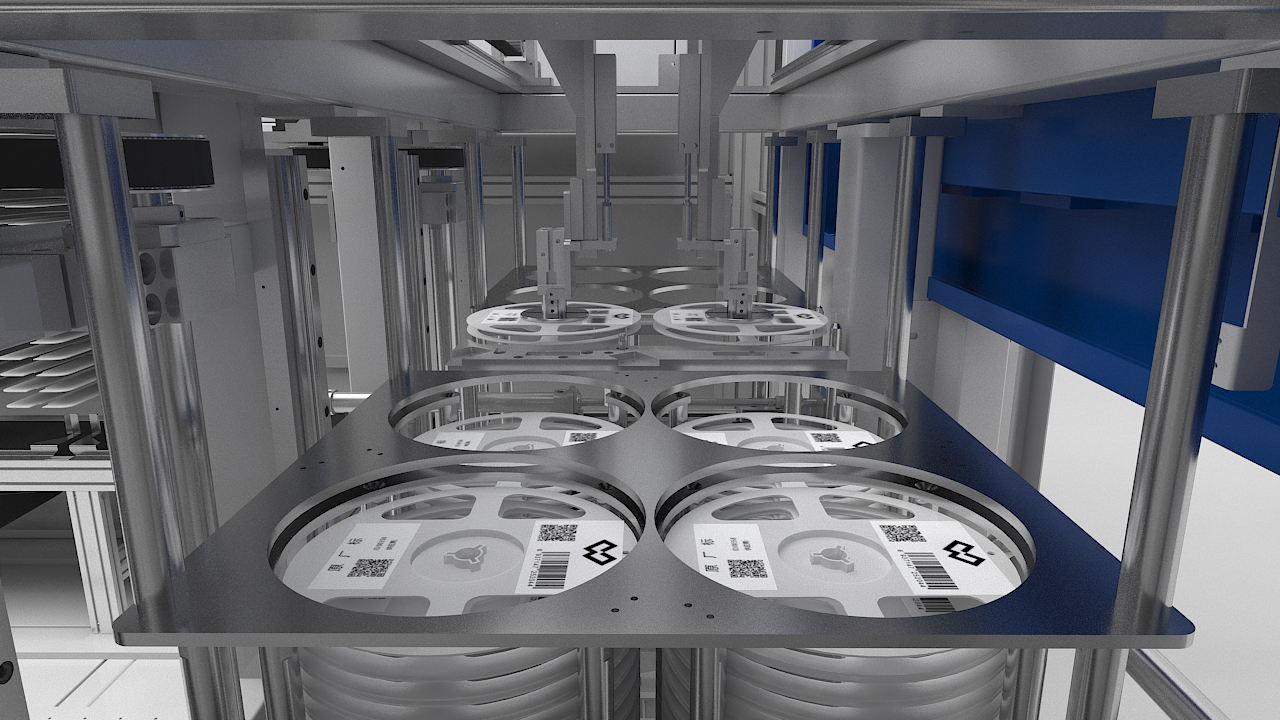

SMT Intelligent automatic warehouse

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc.

|

|

Loading and

Unloading Buffer

|

Up to 180 trays for loading; can be connected to sorting equipment and material handling robots for unloading Up to 180 trays for loading ;

|

|

Efficiency

|

9.5s/reel for storage; 5s/reel for retrieval

|

|

Capacity

|

4000~30000 reels for 7”SMD(Can be customized according to customer requirements)

|

|

Power Supply

|

AC220V(25A)

|

|

Air Pressure

|

0.5MPa clean compressed air (overseas customers can customize according to actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

8000x2100x3000(length and height can be customized on-site)

|

|

Intelligent

Configuration

|

Temperature and humidity detection module / uninterrupted power supply module / in and out of warehouse visual code reading and error prevention module

|

|

Other

|

Double mechanical arms, intelligent avoidance, waiting for storage and retrieval, and other industry-leading technologies

|

|

Remarks

|

Configured with a safety door, which cannot be opened from the outside when the equipment is running. The door can be opened urgently from the inside to the outside.

|

| Parameters |

SMT Intelligent Warehouse (Humidity-sensitive)

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Loading and

Unloading Buffer

|

Two access for loading and unloading materials

|

| Efficiency |

12s/box for storage; 12s/box for retrieval

|

| Capacity |

200~500 storage location(Can be customized according to customer requirements)

|

| Power Supply | AC220V(25A) |

| Air Pressure |

0.5MPa clean compressed air (overseas customers can customize according to actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

8000*2200*2800(length and height can be customized on-site)

|

|

Intelligent

Configuration

|

Temperature and humidity detection module / uninterrupted power supply module / in and out of warehouse visual code reading and error prevention module

|

| Other |

Suitable for precision electronic components or other valuable materials

|

| Remarks | —— |

| Parameters |

Intelligent material storage Rack

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

7~15”SMD;thickness 8mm~ 70mm, customizable

|

|

Error prevention

mechanism

|

inductive/ QR code

|

|

Storage capacity

|

Maximum of 1400/7 layers, with 200 on each layer.

|

|

Power Supply

|

AC220V(3A)

|

|

Dimensions

(L*W*H mm)

|

2400*400*2000

|

| Other |

Materials and colors can be customized, and the sensing materials can monitor the status of material entry and exit in real-time

|

| Parameters |

Mobile Intelligent material Rack

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

7~15”SMD;thickness 8mm~ 70mm, customizable |

|

Error prevention

mechanism

|

inductive/ QR code |

| Storage capacity | 80~200 units, customizable |

| Power Supply |

AC220V(2A)

|

|

Dimensions

(L*W*H mm)

|

1100*400*1200

|

| Other |

Supports wired/wireless communi cationication

|

| Parameters |

Wireless intelligent material picker Rack

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

7~15”SMD;thickness 8mm~ 70mm, customizable

|

|

Error prevention

mechanism

|

inductive/ QR code

|

| Storage capacity |

80~200 units, customizable

|

| Power Supply |

AC220V(3A)Install a power module to provide a battery life of 36 hours.

|

|

Dimensions

(L*W*H mm)

|

1200*850*1250

|

| Other |

Can be used in conjunction with 300-600KG submersible robots.

|

| Parameters |

X-ray SMT component counter (fully-automatic)

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

Diameter:7-15or materials of the same size in a flat state; Height:5mm~70mm

|

|

Efficiency

|

780 reels/hour (mixed loading mode)

|

|

Accuracy

|

99.99% (MIN detectable 01005)

|

|

X-ray

configuration

|

17” flat panel detector with 139μm; VJ source 80KV/100W

|

|

Power Supply

|

AC220V(10A)

|

|

Air pressure

|

0.5MPa clean compressed air (overseas customers can customize according to the actual local power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

4330*1320*2050

|

|

Loading and

Unloading

|

120 reels loading buffer; 120 reels unloading buffe

|

|

Series

Configurations

|

Automatic security access gate; Radiation dose: better than the national standard ≤1uSv/hr

|

|

Other

|

Compatible with online material point function, can also be connected to a printer, built-in 1000W industrial camera, offline labeling to prevent errors.

|

| Parameters |

Double station SMT component counter (semi-automatic)

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

Diameter:7-15or materials of the same size in a flat state; Height:5mm~70mm |

| Efficiency |

1200 reels/hour (7” SMD)

|

| Accuracy |

99.99% (MIN detectable 01005)

|

|

X-ray

configuration

|

17” flat panel detector with 139μm; VJ source 80KV/100W

|

| Power Supply |

AC220V(12A)

|

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to the actual local power supply voltage) |

|

Dimensions

(L*W*H mm)

|

1027*1586*2088

|

|

Loading and

Unloading

|

Manual loading and unloading: 4 reels/7” at a time, 1 reel/13” and above

|

|

Series

Configurations

|

Automatic security access gate; Radiation dose: better than the national standard ≤1uSv/hr |

| Other | Compatible with online material point function, can also be connected to a printer, built-in 1000W industrial camera, offline labeling to prevent errors. |

| Parameters |

Single station SMT component counter(semi-automatic)

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

Diameter:7-15or materials of the same size in a flat state; Height:5mm~70mm |

| Efficiency |

480 reels/hour (7” SMD)

|

| Accuracy |

99.99% (MIN detectable 01005)

|

|

X-ray

configuration

|

17” flat panel detector with 139μm; VJ source 80KV/100W

|

| Power Supply |

AC220V(10A)

|

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to the actual local power supply voltage) |

|

Dimensions

(L*W*H mm)

|

1411*927*2048

|

|

Loading and

Unloading

|

Manual loading and unloading: 4 reels/7” at a time, 1 reel/13” and above

|

|

Series

Configurations

|

Automatic security access gate; Radiation dose: better than the national standard ≤1uSv/hr |

| Other | Compatible with online material point function, can also be connected to a printer, built-in 1000W industrial camera, offline labeling to prevent errors. |

| Parameters |

Automatic labeling machine

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

240 reels/loading; 60 reels/unloading

|

| Efficiency |

1.8s/reel

|

|

Configuration

|

2 sets of 1000w pixel industrial cameras (reading code + verification)

|

|

Sorting

|

Discharge in order, with an NG channel

|

| Power Supply |

AC220V(16A)

|

| Air pressure |

0.5MPa clean compressed air (overseas customers can customize according to local actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

2200*1300*1850

|

|

Operation

|

Suggested for 1 person

|

| Other |

Configured with safety light curtains to protect personnel's safety and comply with EU safety standards.

|

| Parameters |

Automatic labeling and sorting machine

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

240 reels/loading; 90 reels/unloading

|

| Efficiency | 1.8s/reel |

| Configuration |

2 sets of 1000w pixel industrial cameras (reading code + verification)

|

| Sorting |

configured 6-channel sorting discharge + an NG channel

|

| Power Supply | AC220V(16A) |

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to local actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

2350*1550*1900

|

| Operation |

Suggested for 1 person

|

| Other | Configured with safety light curtains to protect personnel's safety and comply with EU safety standards. |

| Parameters |

Universal automatic labeling machine

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

120 reels/loading; 40 reels/unloading

|

| Efficiency |

3.2s/reel

|

| Configuration |

3 sets of 1000w pixel industrial cameras (reading code + verification+ positioning)

|

| Sorting |

Discharge in order, with an NG channel

|

| Power Supply |

AC220V(16A)

|

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to local actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

2950*1850*1880

|

| Operation |

Only requires 1 person to operate

|

| Other | Configured with safety light curtains to protect personnel's safety and comply with EU safety standards. |

| Parameters |

SMD packing machine

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

180 reels/loading reel; 25 reels/unloading reel

|

|

Compatible

material

|

Compatible with 7-13 inch materials.

|

| Efficiency |

8~12s/pcs

|

| Configuration |

4 industrial cameras with 1000w pixel resolution (reading, positioning, and double-checking)

|

|

Power Supply

/Frequency

|

Power supply:AC220V (16A) (can be customized according to the actual power supply voltage of the country of use);frequency: 50HZ.

|

|

Air pressure

|

Air pressure: 0.5-0.7Mpa, flow rate: 120L/min.

|

|

Dimensions

(L*W*H mm)

|

4850*1650*1900 |

|

Sorting Optional

|

sorting by orders/ optional integration with automatic packging equiment |

|

Reading Camera

|

Field of view:180mm*240mm |

|

Reading Efficiency

|

≤600ms

|

| Other |

Only requires 1 person.

|

| Parameters |

Fully compatible labeling production line

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

—— |

|

Compatible

material

|

Compatible with SMD trays of various shapes and sizes within the range of 48cmx42cmx30cm.

|

| Efficiency |

3s/pcs

|

| Configuration |

8 high-speed industrial cameras, 2 4-axis robots, and a multi-position 8-channel sorting system.

|

|

Power Supply

/Frequency

|

Power supply:AC220V (16A) (can be customized according to the actual power supply voltage of the country of use); frequency: 50HZ.

|

| Air pressure |

Air pressure: 0.5MPa clean compressed air (can be customized according to the actual power supply voltage of the country of use).

|

|

Dimensions

(L*W*H mm)

|

15000*5000*1850(can be customized according to customer requirements)

|

| Sorting Optional |

Sort by order with mixed materials.

|

| Reading Camera |

Field of view:180mm*240mm

|

| Reading Efficiency | ≤600ms |

| Other |

Recommended 3 people

|

| Parameters |

Desktop ticket machine

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

7”SMD

|

| Efficiency |

3.5-5s/pcs (depending on the operator's proficiency)

|

| Configuration |

2 sets of 1200w pixel industrial cameras (code reading + positioning + verification)

|

|

Power Supply

|

AC220V (10A) (overseas customers can customize according to the actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

600*450*650

|

| Other |

Suitable for electronic component distributors and SMT factories for small-batch coding and labeling

|

| Parameters |

Vertical Ticket machine (Dual-Station Dual-Side)

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

diameter: 7”-17”, height: 10-300mm (with laser focusing module, automatically adapts to material height)

|

| Efficiency |

3.5-5s/pcs (depending on the operator's proficiency)

|

| Configuration |

4 sets of 2000w pixel industrial cameras (code reading + positioning + verification)

|

| Power Supply | AC220V (10A) (overseas customers can customize according to the actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

1250*1100*1860

|

| Other |

able to read side label barcodes simultaneously

|

| Parameters |

Vertical Ticket Printer (Dual-Station Single-Side)

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc.

|

|

Compatible

material

|

diameter: 7”-17”, height: 10-300mm (with laser focusing module, automatically adapts to material height) |

| Efficiency |

3.5-5s/pcs (depending on the operator's proficiency)

|

| Configuration |

2 sets of 2000w pixel industrial cameras (code reading + positioning + verification)

|

| Power Supply | AC220V (10A) (overseas customers can customize according to the actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

960*1100*1980

|

| Other |

Suitable for electronic component distributors and SMT factories for small-batch coding and labeling

|

| Parameters |

Hi-speed ticket checking machine

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

diameter: 7”-17”, height: 10-300mm (with laser focusing module, automatically adapts to material height) |

| Efficiency |

1s/pcs

|

| Configuration |

1 set of 2000w pixel industrial global camera

|

| Power Supply | AC220V (10A) (overseas customers can customize according to the actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

1800*800*1950

|

| Other |

suitable for reviewing and checking material information.

|

| Parameters |

Intelligent Soler Paste Cabinet

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

Bottled materials

|

|

Error prevention

mechanism

|

inductive/ QR code

|

|

Storage capacity

|

—— |

| Power Supply |

AC220V(16A)(Overseas users can customize according to the actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

2000*1500*2000(Length and height can be customized on site)

|

| Other |

Equipped with wired and wireless data communication interfaces such as Ethernet port, serial port, USB, WIFI material )

|

|

Refrigeration

|

Can be controlled from 2℃~10℃, and the refrigeration temperature can be freely set)

|

|

Refrigeration

Temperature

|

2℃~10℃

|

|

Refrigeration

Capacity

|

300 bottles

|

|

Temperature of

Warm-up Box

|

18℃~20℃

|

|

War,-up

Box capacity

|

60 bottles

|

|

Energy Storage

Device

|

UPS

|

| Parameters |

Intelligent Tray material Cabinet

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

7”~17“;thickness 8mm~75mm, Customizable

|

|

Error prevention

mechanism

|

inductive/ QR code

|

| Storage capacity |

96 slot

|

| Power Supply |

AC220V(3A)(Overseas users can customize according to the actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

2420*400*1900

|

| Other |

Color can be Customized; the inductive material can monitor the entry and exit status in real time

|

| Parameters |

Intelligent stencil storage Cabinet

|

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

Compatible with tray, bag and box materials

|

|

Error prevention

mechanism

|

inductive/ QR code |

| Storage capacity |

76 steel mesh storage; 2 layer steel mesh cabinet

|

| Power Supply |

AC220V(3A)(Overseas users can customize according to the actual power supply voltage)

|

|

Dimensions

(L*W*H mm)

|

2996*820*1934

|

| Other |

Hinge double door

|