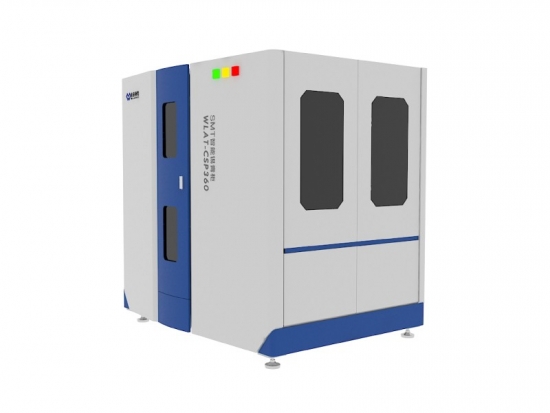

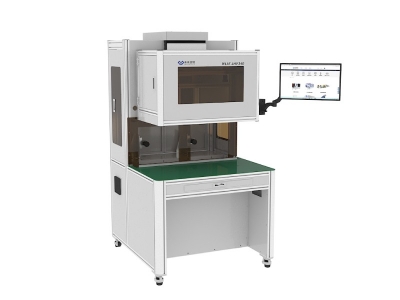

Intelligent Solder Paste Cabinet solutions

Total process automation

-

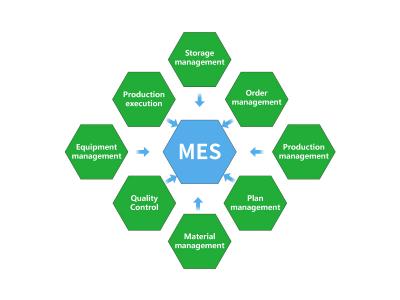

Intelligent management

Automatic management of the entire process, such as code scanning, refrigeration, paste reservation, tempering and mixing

Intelligent management

Automatic management of the entire process, such as code scanning, refrigeration, paste reservation, tempering and mixing

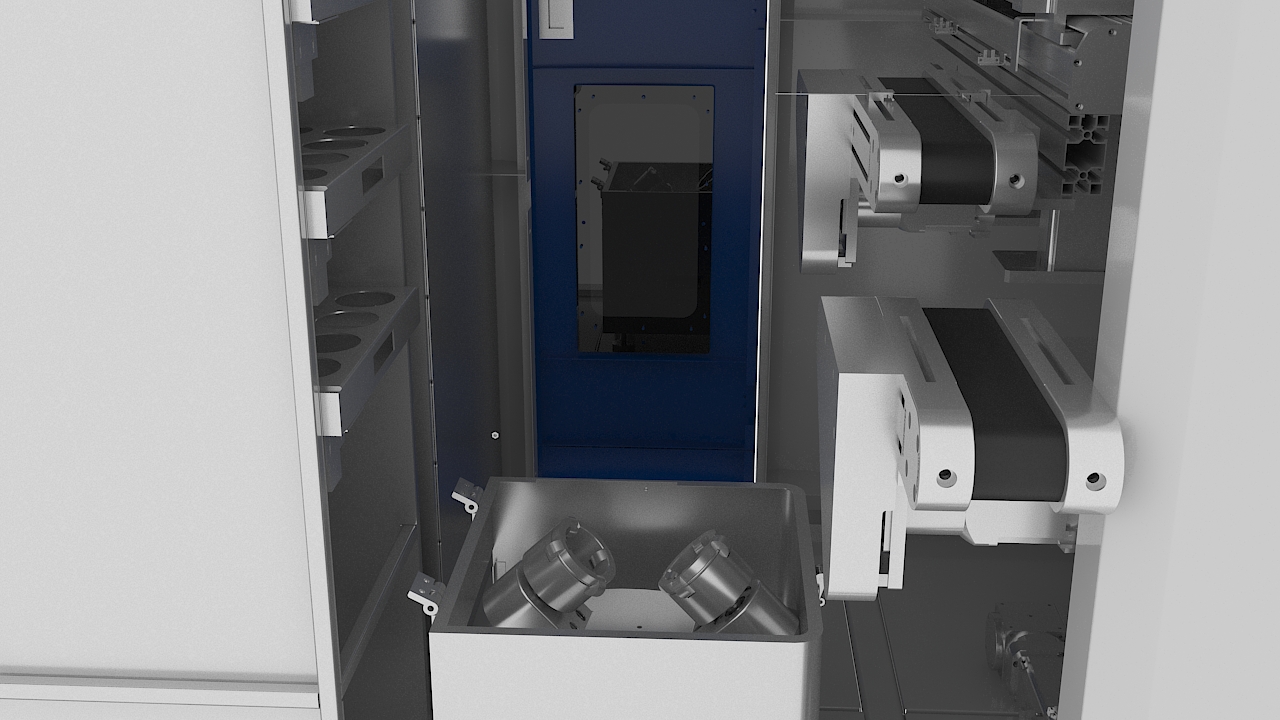

1. manual storage of materials;

2. visual code scanning and automatic data entry;

3. MES docking, system automatic appointment time monitoring, automatic flow in the warehouse;

4. automatic chilling and retempering according to set times

5. automatic time monitoring of refrigerating and re-tempering, automatic indication that re-tempering is complete and ready for mixing;

6. automatic mixing of ingredients from the reheating zone when picking up ingredients;

7. manually remove the material that has been stirred, the system synchronized to review;

8. the material is fed into the production line.

Functional features

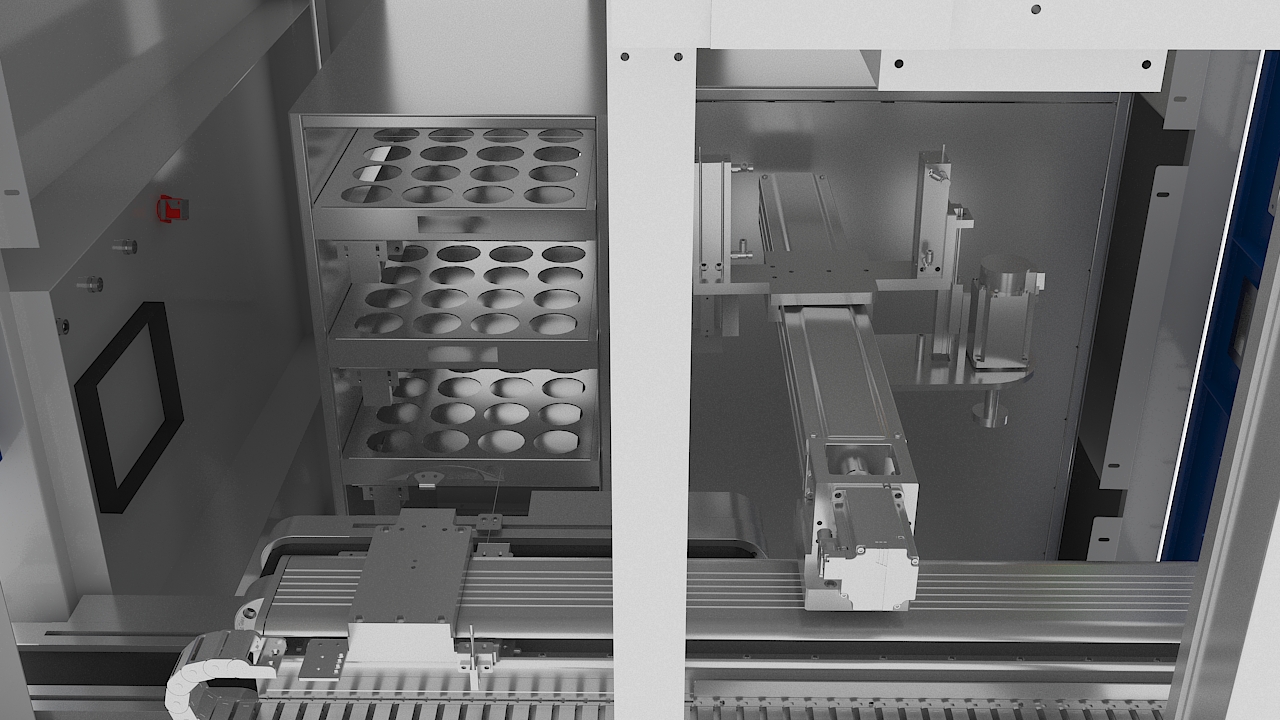

l Refrigeration: the equipment can be controlled from 2℃ to 10℃, and the refrigeration temperature can be set freely.

l Return temperature: set the return temperature zone, consistent with the use of temperature environment.

l Stirring: the stirring time can be set by hand.

l UPS: ensure that the guaranteed equipment does not lose data in case of sudden power failure, and the mechanical actuator automatically returns to the original point after completing the programmed action.

l Operation and operation process can be traced, two-dimensional code marking printing Used to identify the attributes of the solder paste, including the purchaser, manufacturer, ingredient content, capacity, warranty period and other information.

l Equipped with: network port, serial port, USB, WIFI and other wired and wireless data communication interfaces.

l Human-machine interaction (HMI) touch screen interface for equipment operation.

l System can be interfaced with any WMS, ERP, MES, etc.

l Timing and quantitative control of the process engineering of solder paste preparation and storage, greatly reducing manpower and time costs.

|

|

Scope of application

Used in the electronic components industry, mainly in SMT factories.

| Parameters | Intelligent Solder Paste Cabinet |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

Bottled materials |

|

Error prevention

mechanism

|

inductive/ QR code |

| Storage capacity | —— |

| Power Supply | AC220V(16A)(Overseas users can customize according to the actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

2000*1500*2000(Length and height can be customized on site) |

| Other | Equipped with wired and wireless data communication interfaces such as Ethernet port, serial port, USB, WIFI material ) |

| Refrigeration | Can be controlled from 2℃~10℃, and the refrigeration temperature can be freely set) |

|

Refrigeration

Temperature

|

2℃~10℃ |

|

Refrigeration

Capacity

|

300 bottles |

|

Temperature of

Warm-up Box

|

18℃~20℃ |

|

War,-up

Box capacity

|

60 bottles |

|

Energy Storage

Device

|

UPS |