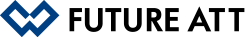

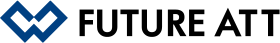

SMT Automatic Labeling and Sorting Conveyor Line solution

utomatic feeding, code scanning, labeling, review, sorting, cutting

-

2. Automatic code readingThe material is transported to the reading station, the industrial camera locates and reads the code, the system sends the The material is transported to the reading station to read the code, the system sends the The material is transported to the reading station The material is transported to the reading The material is transported to the reading Material conveying to the reading station, system printing labels;

2. Automatic code readingThe material is transported to the reading station, the industrial camera locates and reads the code, the system sends the The material is transported to the reading station to read the code, the system sends the The material is transported to the reading station The material is transported to the reading The material is transported to the reading Material conveying to the reading station, system printing labels; -

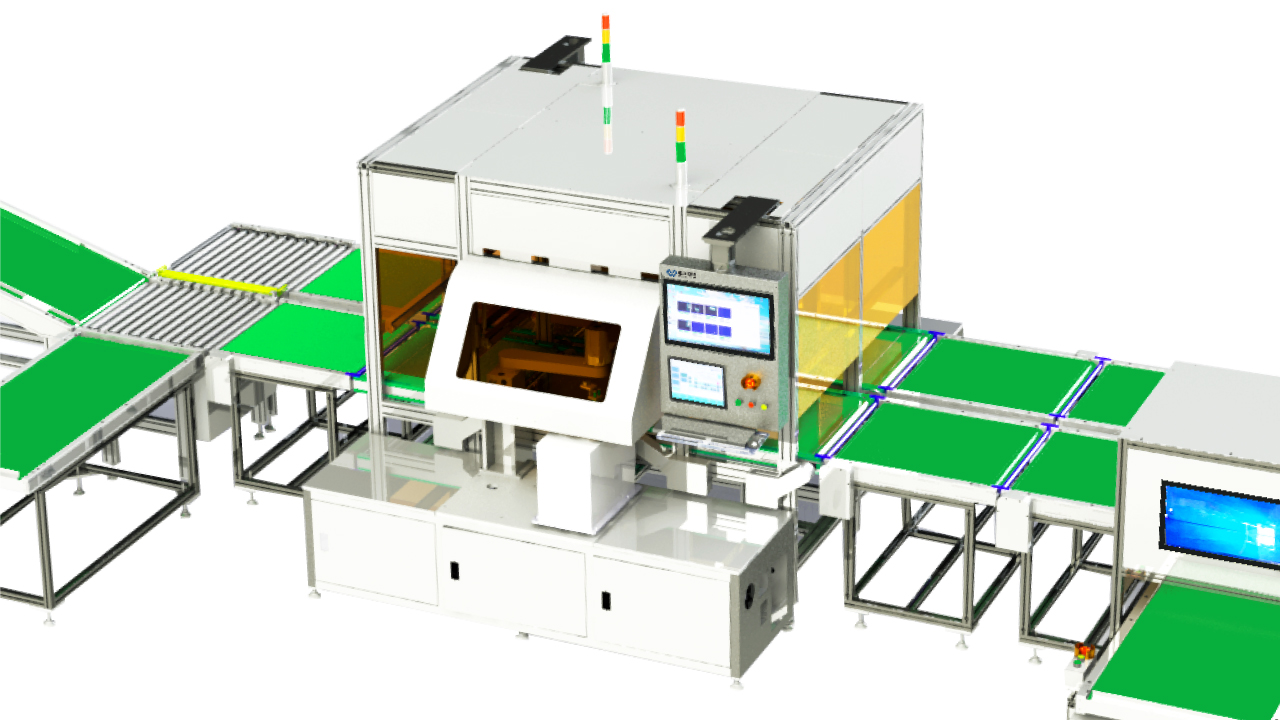

3. Automatic labelingThe material is transported to the labeling review area to label the tray;

3. Automatic labelingThe material is transported to the labeling review area to label the tray;

-

4. Automatic reviewThe industrial camera identifies the plate The industrial camera identifies the plate label The industrial camera identifies the plate The The camera identifies the plate label and sends the result to the system;

4. Automatic reviewThe industrial camera identifies the plate The industrial camera identifies the plate label The industrial camera identifies the plate The The camera identifies the plate label and sends the result to the system; -

5. Automatic sortingQualified, transported to the sorting area; Reject to NG product storage tank;

5. Automatic sortingQualified, transported to the sorting area; Reject to NG product storage tank; -

6.Automatic cuttingAutomatic cutting, manual labeling Automatic Automatic blanking, manual labeling (outlet reserved for docking box channel)

6.Automatic cuttingAutomatic cutting, manual labeling Automatic Automatic blanking, manual labeling (outlet reserved for docking box channel)

Functional features

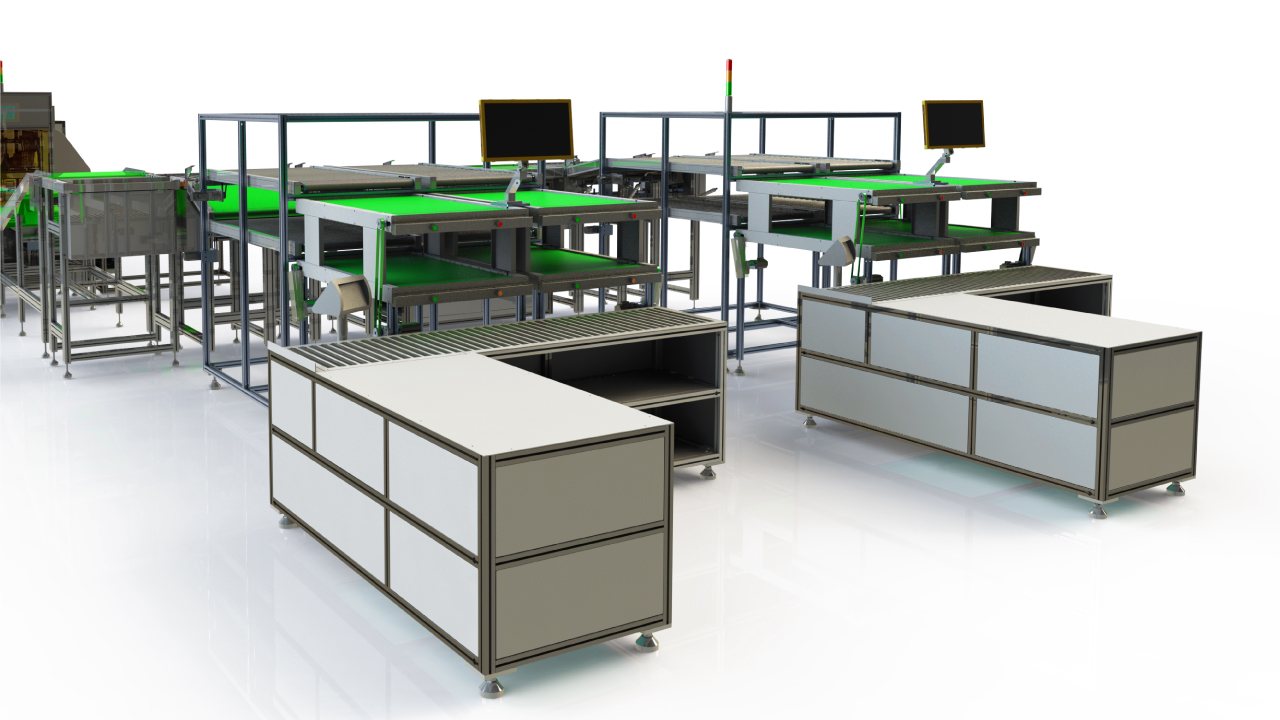

l Suitable for all kinds of SMD trays in boxes and bags within the size range of 48cmx42cmx30cm

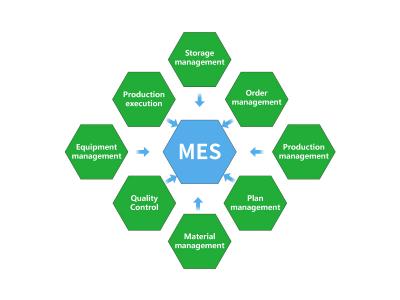

l The system can be connected with any WMS, ERP, MES, etc

l High labeling efficiency and stable performance

l The whole process of automatic code scanning, labeling, review, cutting

l Support mixed feeding, sorting by order

l Equipped with 8 industrial cameras +2 4-axis robots + multi-station 8-channel sorting system, equipped with NG channel to meet the accuracy requirements

l Recommended for 3 persons

Fully compatible labeling assembly line, to meet the customer order quantity, material tray types, diverse forms, to deal with high order timeliness, order types, large personnel input and other problems, to solve the multi-scene material delivery needs.

|

|

Scope of application

For electronic components (compatible with various types and sizes of boxed and bagged SMD trays) automatic customer labeling. Available for original manufacturers and distributors.

| Parameters | SMT Automatic Labeling and Sorting Conveyor Line |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

Compatible with SMD trays of various shapes and sizes,within the range of 48cmx42cmx30cm. |

| Efficiency | 3s/reel |

| Configuration | 8 high-speed industrial cameras, 2 4-axis robots, and a multi-position 8-channel sorting system. |

|

Power Supply

/Frequency

|

Power supply:AC220V (16A) (can be customized according to the actual power supply voltage of the country of use);frequency: 50HZ. |

| Air pressure | Air pressure: 0.5MPa clean compressed air (can be customized according to the actual power supply voltage of the country of use). |

|

Dimensions

(L*W*H mm)

|

15000*5000*1850(can be customized according to customer requirements) |

| Sorting Optional | Sort by order with mixed materials. |

| Reading Camera | Field of view:180mm*240mm |

| Reading Efficiency | ≤600ms |

| Other | Recommended 3 people |