The MES system is a production information management system for manufacturing enterprises at the shop floor level. mes system adopts a powerful data collection engine and integrates data collection channels (RFID, barcode equipment, PLC, Sensor, IPC, PC, etc.) to cover the entire factory manufacturing site, ensuring real-time, accurate and comprehensive collection of massive on-site data.

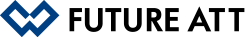

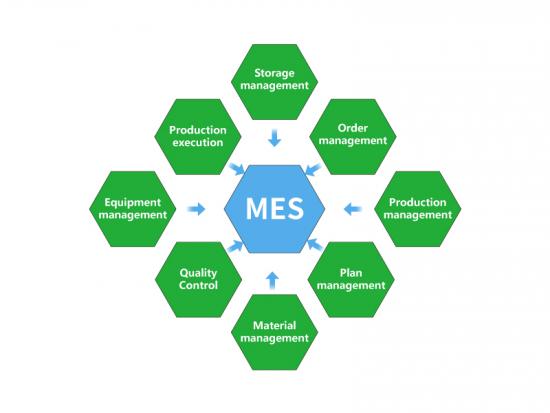

The MES system is a production information management system for the shop floor of manufacturing enterprises, which can provide manufacturing data management, planning and scheduling management, production management, inventory management, quality management, human resources management, work centre/equipment management, tooling management, purchasing management, cost management, project kanban management, production process control, bottom data integration and analysis, upper data integration and decomposition, etc, The management modules, such as the integration and decomposition of upper-level data, create a solid, reliable, comprehensive and feasible collaborative manufacturing management platform for enterprises.

Features

1) Adopt powerful data collection engine and integrate data collection channels (RFID, barcode devices, PLC, Sensor, IPC, PC, etc.) to cover the entire factory manufacturing site, ensuring real-time, accurate and comprehensive collection of massive on-site data.

2) Create a basic platform for data collection in the factory production management system, with good scalability.

3) Adopt advanced RFID, barcode and mobile computing technologies to create a closed-loop barcode system from raw material supply, production and sales logistics.

4) Comprehensive and complete product tracking and tracing function.

5) Production WIP status monitoring.

6) Just-In-Time inventory management and Kanban management.

7) Real-time, comprehensive and accurate performance and quality analysis SPC.

NET platform and supports mainstream databases such as Oracle/SQL Sever. The system is a combination of C/S structure and B/S structure, easy to install and upgrade.

9)Personalized factory information portal (Portal), through the WEB browser, you can master the production site real-time information at any time and anywhere.

10) Strong MES technical team to ensure fast implementation and reduce project risks.

System features

Connectivity, connecting people, machines, materials and methods, providing real-time feedback on production and real-time production instructions

Control, effectively strengthen the whole process of product manufacturing management, to achieve enterprise-level closed-loop management

Optimisation, based on real-time historical data collected from people, machines, materials, methods and the environment, to assist managers in decision-making

Function overview

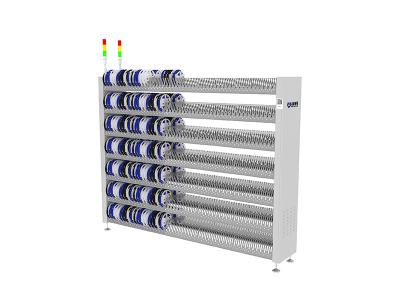

Data collection

This includes both automatic collection and manual feedback. Automatic collection supports a wide range of industrial protocols, allowing real-time collection of equipment information and processing part information.

Quality traceability

The data from each collection point of the production line is statistically analysed to provide users with a complete product traceability system.

Production control

Through different levels of planning management and advanced scheduling methods, we can make full use of the various production resources in the enterprise, coordinate various production factors and ensure balanced production through flexible production scheduling, thus achieving increased production capacity and efficiency.

Material Control

We strengthen logistics control methods and establish an agile supply chain within the enterprise; through material alignment analysis and control, we ensure the timeliness and completeness of material supply to ensure on-time delivery of products.

Quality Control

Adopt the idea of "active and comprehensive quality management" to achieve comprehensive quality control that is preventable beforehand, controllable during the process and traceable afterwards.

Resource management

Effective management of the company's various production resources to ensure efficient and rational use of resources.

Efficiency management

Monitoring the overall efficiency (OEE) of each machine/line and other key indicators such as downtime, scrap rate, yield, etc.