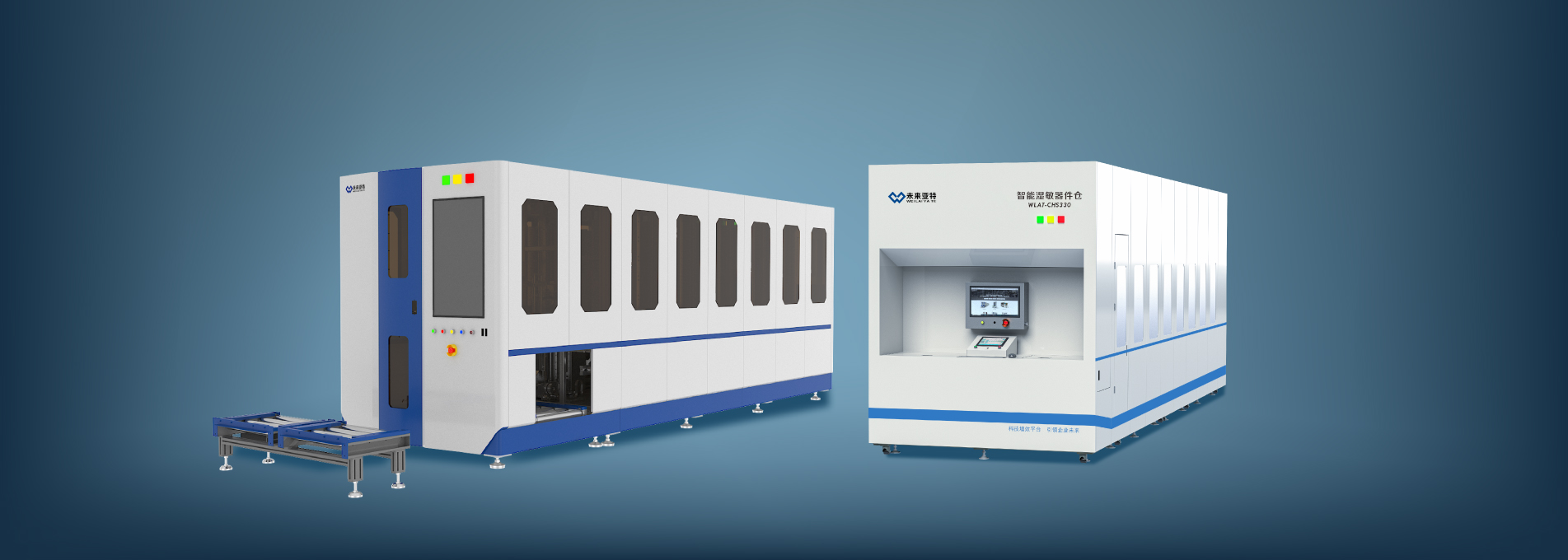

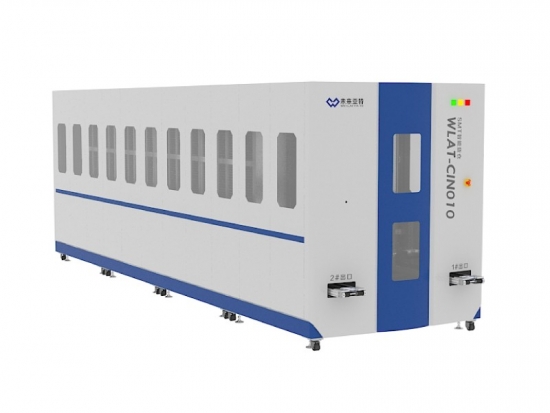

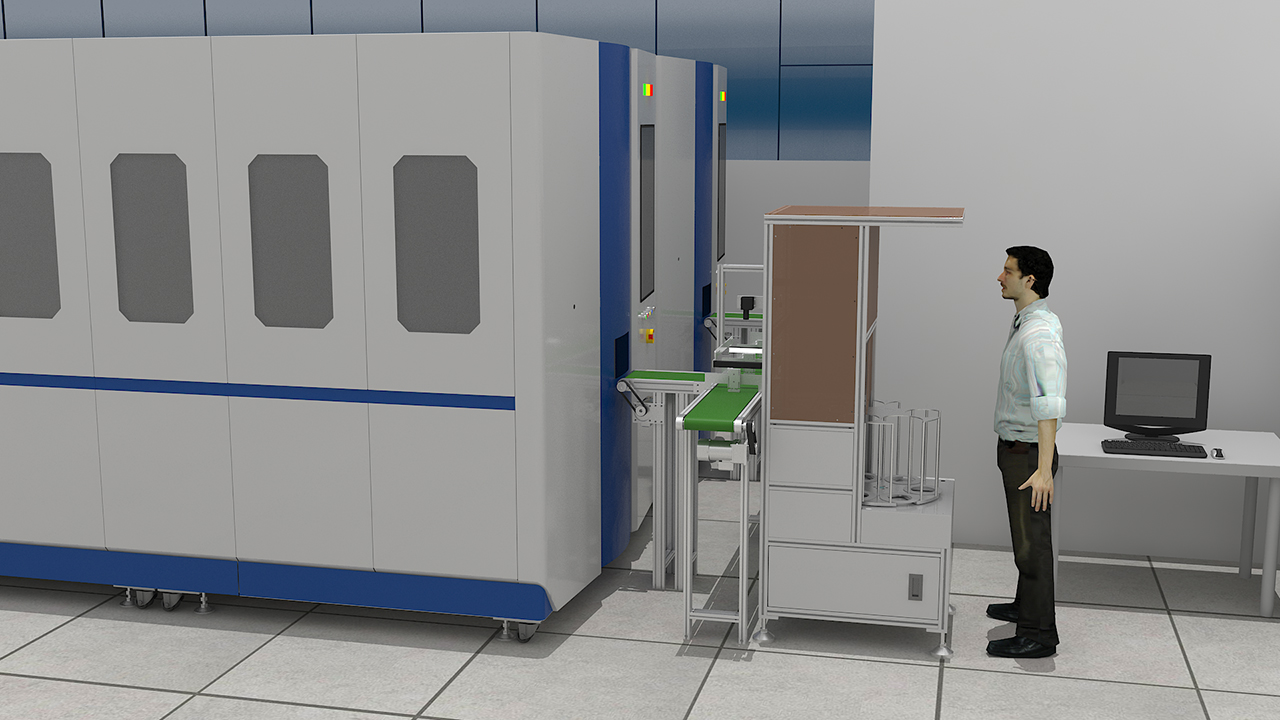

SMT Smart Warehouse Solution

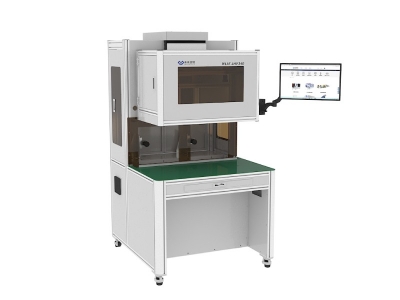

Solve the problem of high precision access to wire-side bins

-

Constant temperature management

Equipped with temperature and humidity management module to prevent moisture and electricity

Constant temperature management

Equipped with temperature and humidity management module to prevent moisture and electricity

-

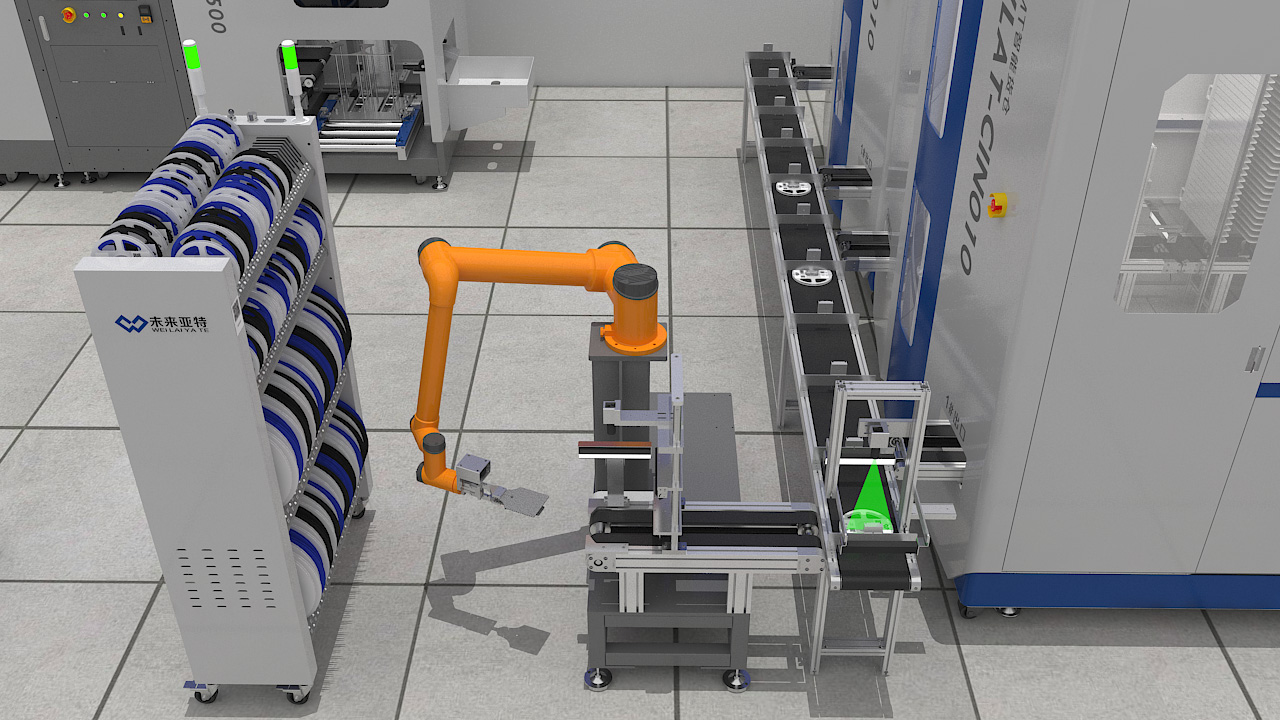

1. Manual loading / robotic loadingThe material tray is placed at the incoming Whatever you needs, CARESTONE is at your side.

1. Manual loading / robotic loadingThe material tray is placed at the incoming Whatever you needs, CARESTONE is at your side. -

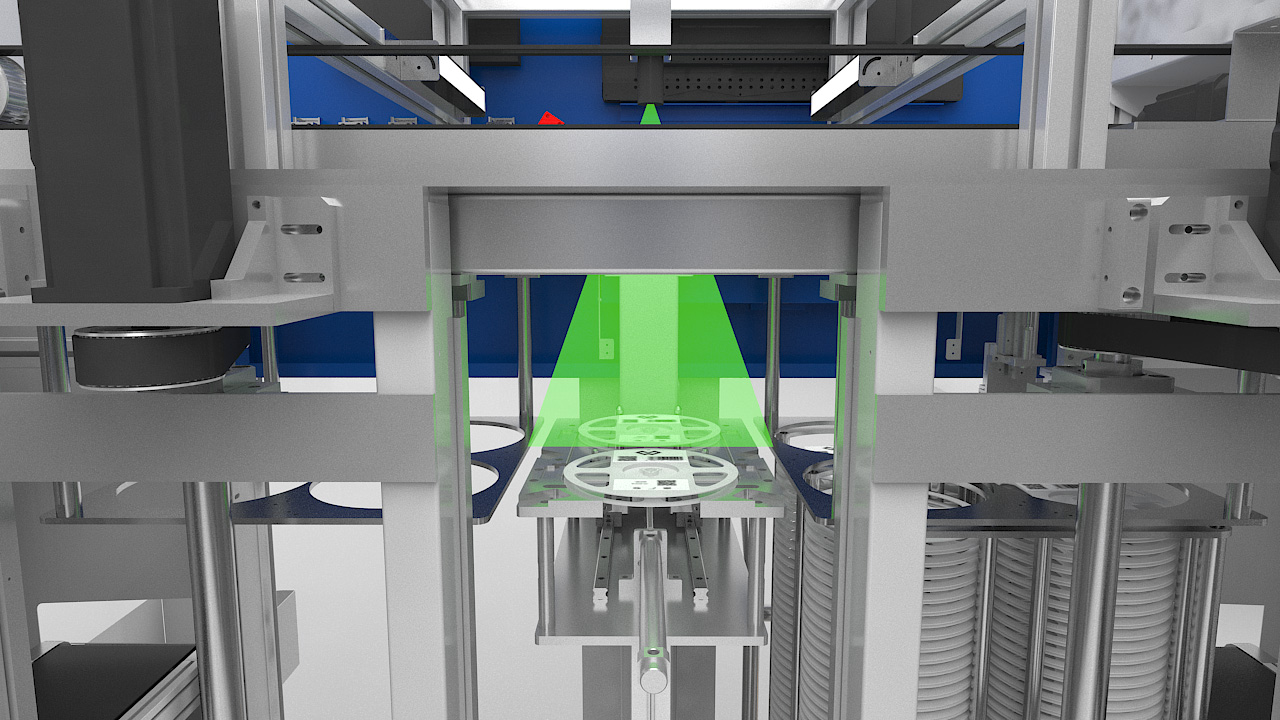

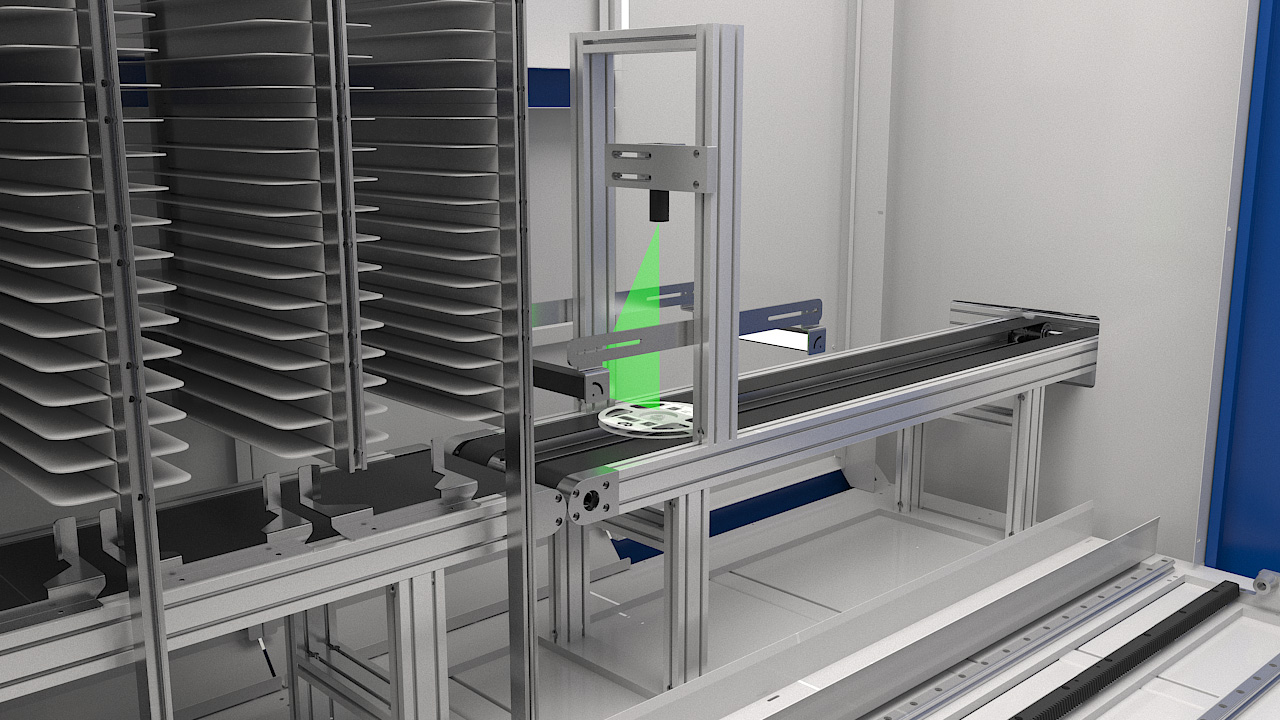

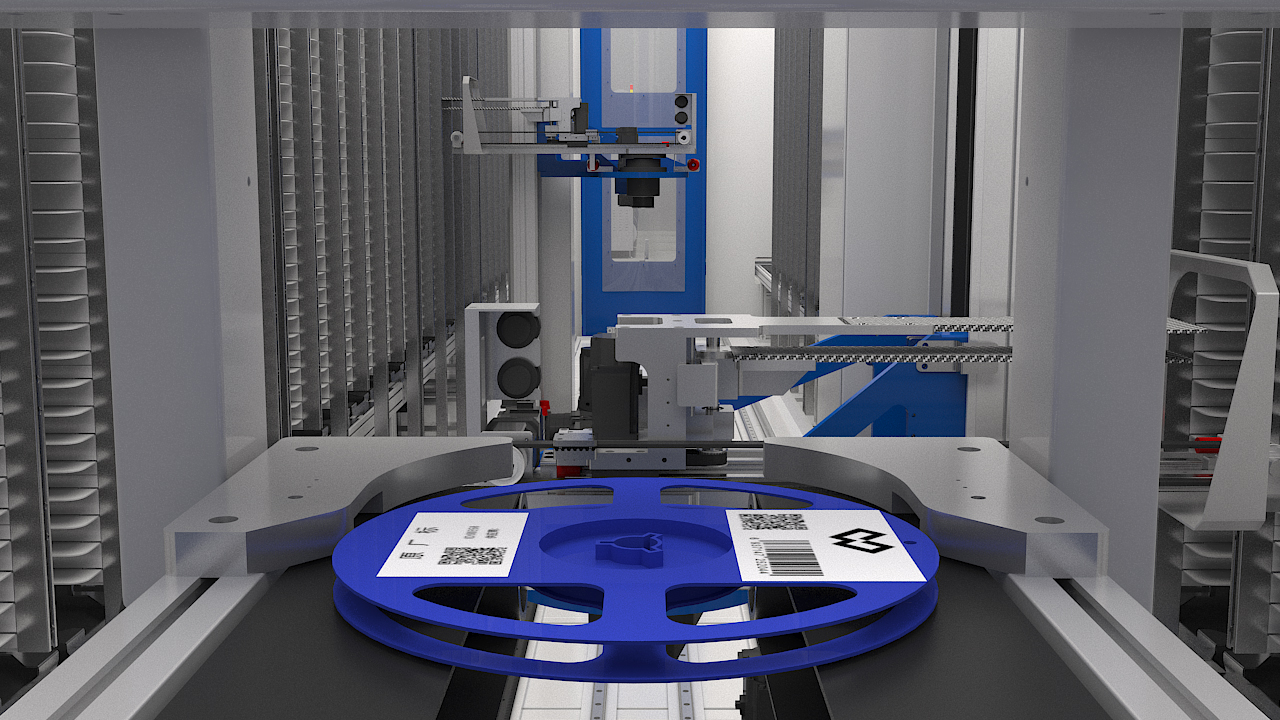

2. Scan codeThe robot takes the material tray to the code reading station and the equipment automatically takes pictures and reads the code;

2. Scan codeThe robot takes the material tray to the code reading station and the equipment automatically takes pictures and reads the code; -

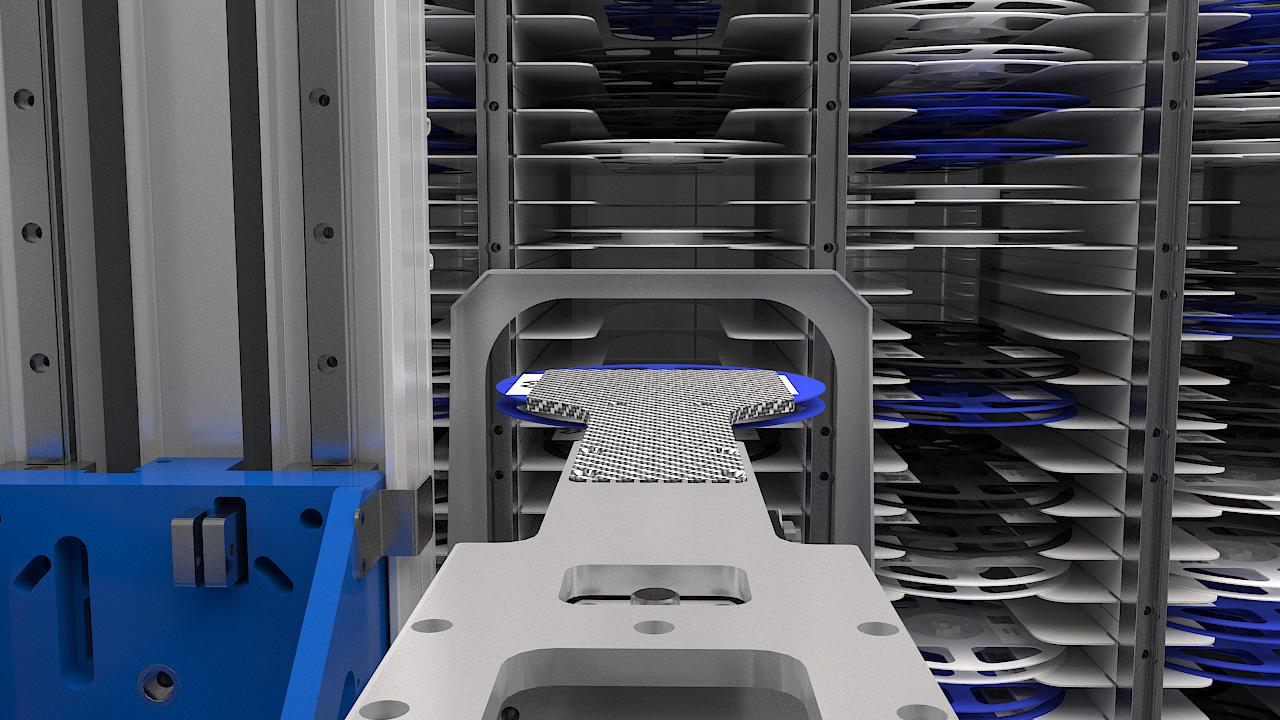

3、StorageThe mechanical arm of the roadway will grab the material tray and send it to the designated storage location to complete the storage; The aisle robotic arm will pick up the material tray and send it to the designated storage position to complete the storage;

3、StorageThe mechanical arm of the roadway will grab the material tray and send it to the designated storage location to complete the storage; The aisle robotic arm will pick up the material tray and send it to the designated storage position to complete the storage;

-

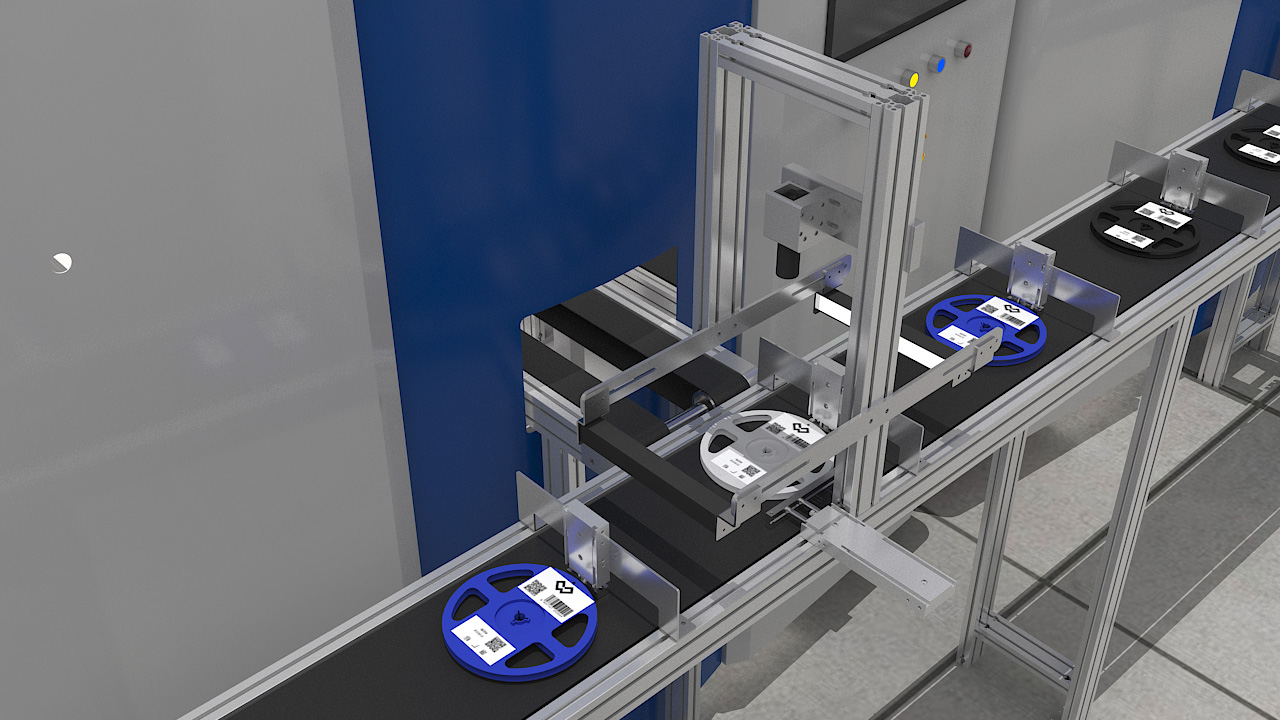

4、DischargeThe system automatically mobilises the lane mechanical arm According to the demand, the aisle mechanical arm will pick up the trays and put them into the outgoing conveyor belt;

4、DischargeThe system automatically mobilises the lane mechanical arm According to the demand, the aisle mechanical arm will pick up the trays and put them into the outgoing conveyor belt; -

5、Out of the warehouse reviewThe trays are transported to the outbound review position and automatically photographed and code read for review;

5、Out of the warehouse reviewThe trays are transported to the outbound review position and automatically photographed and code read for review; -

6、Finish the outgoing storageAfter checking, the trays are sent out and dropped into the receiving frame or connected to other conveyor belts. connected to other conveyor belts.

6、Finish the outgoing storageAfter checking, the trays are sent out and dropped into the receiving frame or connected to other conveyor belts. connected to other conveyor belts.

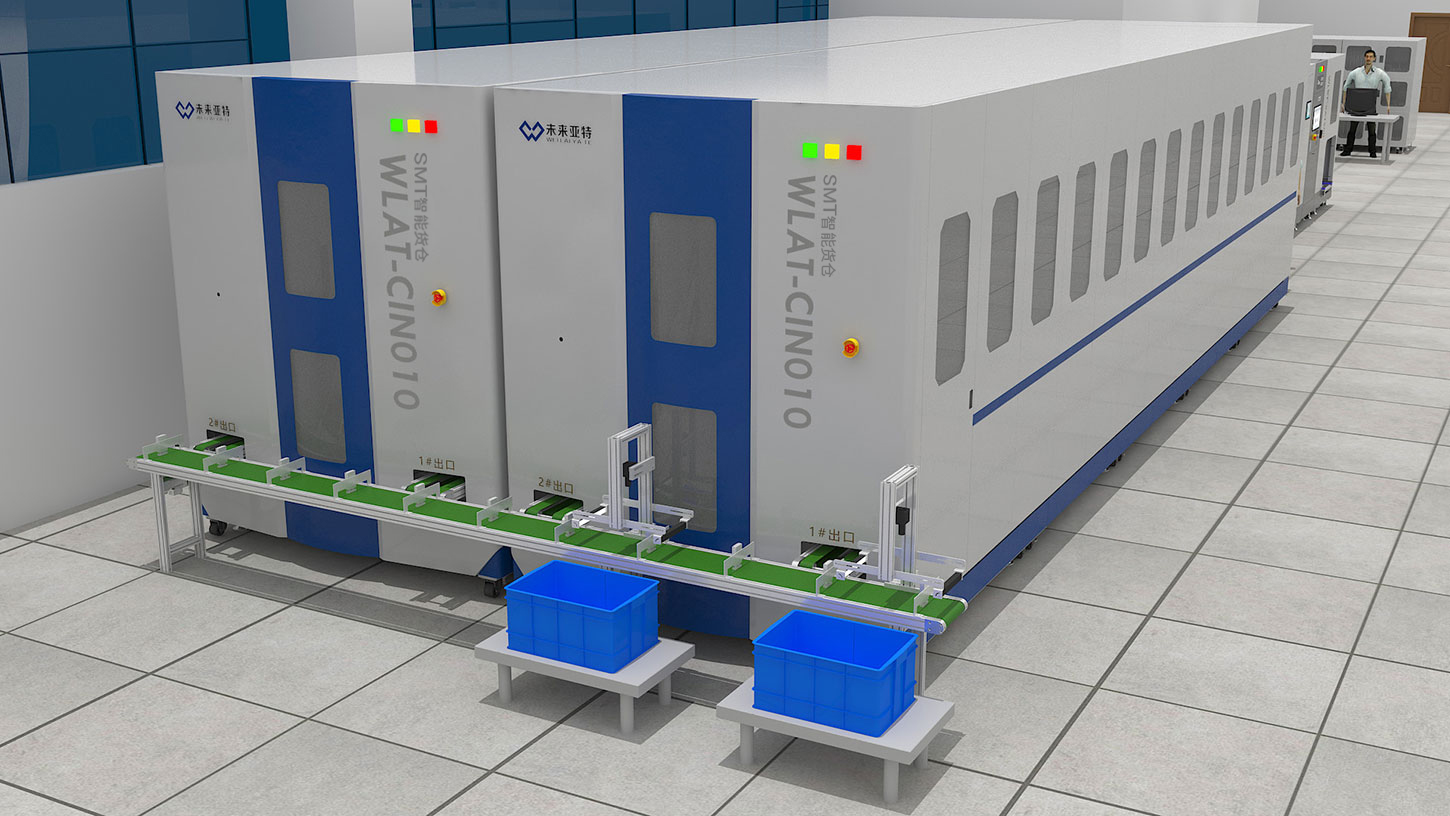

The whole process of automatic storage, automatic batching, to achieve accurate management of materials, combined with the material R-ID can automatically send orders to the plate, first in first out, according to the number of demand to send materials; optional temperature and humidity management module, constant temperature and humidity management of materials; incoming materials after the material management shelves, work orders to prepare materials, secondary sorting of tail material, tail material finishing back to the warehouse, asset inventory and other links, according to the system instructions, receive BOM orders automatically picking materials, double channel under the material, can Docking with AGV picker + robot to automatically send materials to the production line, using intelligent storage equipment instead of personnel operation, greatly improving efficiency.

Functional features

l R-ID generation can be dispatched to the tray, first in first out, to achieve accurate management of materials

l Equipped with temperature and humidity management module, which can manage materials at a constant temperature to ensure material quality

l The whole process of dummy-proof and error-proof, 100% accuracy rate

l Adopt unique code, material traceability

l Intelligent operation, reducing labour and improving efficiency

l Simple and easy to operate, only 1 person is needed

|

|

Scope of application

Automatic storage and dosing of a wide range of electronic components for the SMT industry (compatible with 7 to 13 inch pallets)

| Parameters | SMT Intelligent automatic warehouse |

|

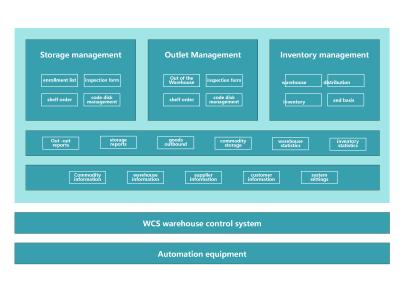

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Loading and

Unloading Buffer

|

Up to 180 trays for loading; can be connected to sorting equipment and material handling robots for unloading Up to 180 trays for loading ; |

| Efficiency | 9.5s/reel for storage; 5s/reel for retrieval |

| Capacity | 4000~30000 reels for 7”SMD(Can be customized according to customer requirements) |

| Power Supply | AC220V(25A) |

| Air Pressure | 0.5MPa clean compressed air (overseas customers can customize according to actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

8000x2100x3000(length and height can be customized on-site) |

|

Intelligent

Configuration

|

Temperature and humidity detection module / uninterrupted power supply module / in and out of warehouse visual code reading and error prevention module |

| Other | Double mechanical arms, intelligent avoidance, waiting for storage and retrieval, and other industry-leading technologies |

| Remarks | Configured with a safety door, which cannot be opened from the outside when the equipment is running. The door can be opened urgently from the inside to the outside. |