What are the requirements for the side warehouse of the SMT production line?

September 05,2023With the popularity and upgrading of electronic products, SMT production lines have gradually become the most commonly used production method in the electronics manufacturing industry, undertaking multiple tasks such as material storage, supply and management.

In the SMT production line, due to the wide variety and large quantity of various components, lineside warehouses are required to store and manage materials. The line side warehouse is located next to or near the SMT production line, closely cooperates with the production line, provides high-density storage space and material replenishment tasks, and realizes functions such as material information traceability, inventory management, and warehouse entry and exit records.

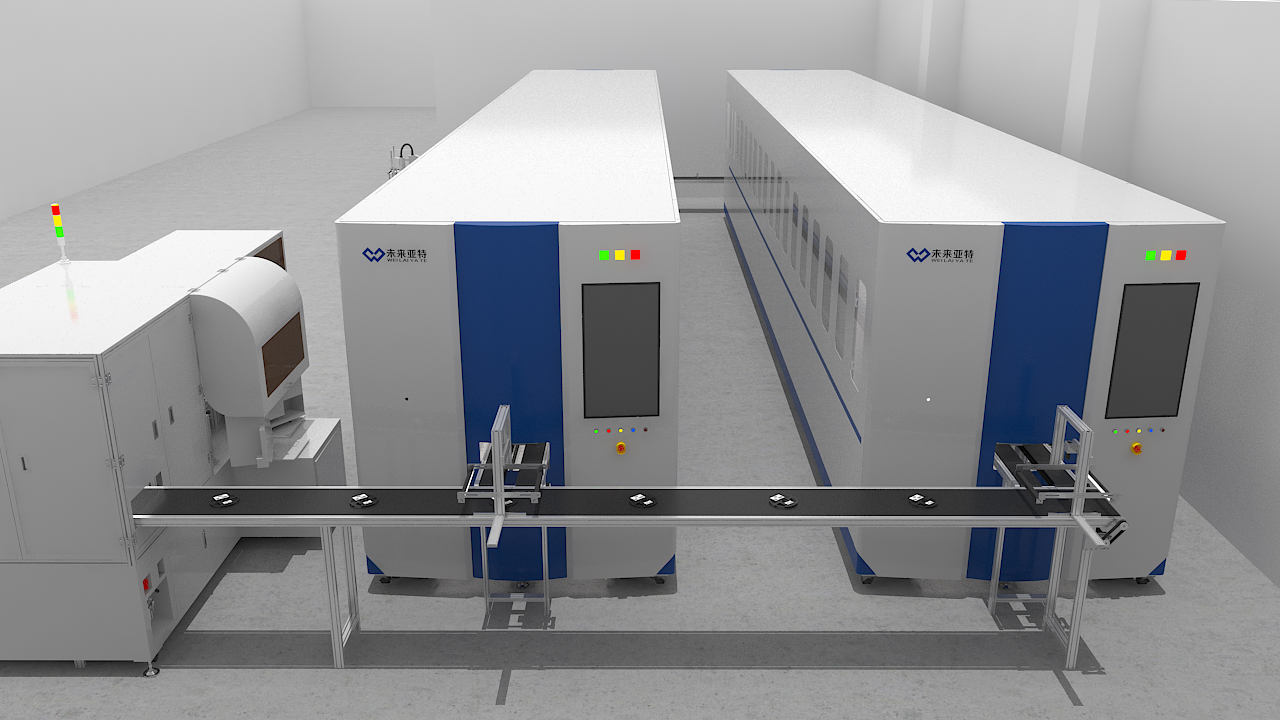

Future Att will provide overall SMT intelligent warehousing solutions to meet various problems encountered during the production process.

1、Provide special requirements to meet the material environment:

Temperature control: Since some special materials will be affected by temperature and cause problems such as failure or deformation, the temperature range must be controlled during use;

Humidity control: Too high humidity will cause some components to be damaged by moisture. You must also pay attention to controlling the humidity range during use;

Dust-proof and anti-static: some components are very sensitive, as long as they are slightly exposed to static electricity, they will be damaged or invalid;

2、To realize the efficient and stable operation of the production process, the standard requirements for management:

Material management: adopt the method of one person in one warehouse, one yard in one warehouse, to make material management more accurate;

Refined inventory management: adopt the first-in-first-out method to prevent material hoarding and other phenomena, and at the same time monitor the material inventory in real time and adjust it according to actual needs;

Improvement of inbound and outbound records: all inbound and outbound materials are recorded in real time, and the data can be viewed in real time;

Smart electronic rack

1. Provide services to meet the needs of frequent material pick-up and placement:

Inductive/light-up storage: provide efficient and accurate support for frequent picking and placing of materials on the production line;

Reduce labor force: cooperate with AGV to send to the production line to improve production efficiency;

Improve space utilization: take advantage of vertical space to facilitate operators to pick up and place materials;

2. Provide standard management requirements that meet the efficient and stable operation of production:

Material management: adopt the method of one person in one warehouse, one yard in one warehouse, to make material management more accurate;

Improvement of inbound and outbound records: all inbound and outbound materials are recorded in real time, and the data can be viewed in real time;

Refined inventory management: adopt first-in-first-out method to prevent hoarding of materials and other phenomena