Future Att appeared in the 88th CEIA China Electronic Intelligent Manufacturing Summit Forum

Aug 02,2023On November 24, the 88th CEIA China Electronics Intelligent Manufacturing Summit Forum was successfully held in Suzhou. Liu Xiping, deputy general manager of Future Att, attended and delivered a speech, sharing with you how to help the production line realize intelligent upgrade through the ecological construction of intelligent storage in the electronics industry.

Facing the transformation of manufacturing in the electronics industry, it is an important trend to create digital and intelligent production solutions.

At the meeting, Liu Xiping, the deputy general manager of Future Att, took "Smart Manufacturing-SMT Smart Warehousing Overall Solution" as the theme, and pointed out that there are still many electronic manufacturing companies at this stage, in the multiple links of warehouse receiving, sending, retrieving, and storage. There are problems such as low efficiency of manual collaboration, high error rate, untimely information management, and material turnover management. How to realize lean production of the production line has become a problem that needs to be solved at present.

|

|

Future Att will provide a one-stop overall solution based on years of research and development and accumulation of intelligent storage ecological construction, combined with its own and enterprise project experience, and realize the interconnection and intercommunication of equipment and software through the collaborative operation of different intelligent terminal equipment, and lean collaborative production , to facilitate the flexible management of the production line.

The development trend of intelligent warehousing in the electronics industry

As customized orders in the electronics industry become an important part of market demand, the electronics manufacturing industry passively accepts overall industrial upgrades, and adjustments need to be made to meet the mainstream needs of the market from product design to production and manufacturing.

At present, the overall development of my country's warehousing industry is still in the stage of automated warehousing. Therefore, deepening the collaborative innovation among industrial supporting conditions and promoting the concentration and effective integration of industry supporting resources are still the key to the competitive advantage of the intelligent warehousing industry in the future.

The overall solution of factory intelligent warehousing

Future Att, as a professional SMT intelligent storage overall solution manufacturer, products include intelligent labeling equipment, intelligent storage equipment, intelligent pointing equipment, etc., to help the production line realize automatic management. Solve the problems and requirements faced in the production process:

●Large order volume: peak period/seasonal, large order, short cycle

●Difficulty in recruiting: Solve the shortage of labor, high mobility and high cost

●Low efficiency: low manual work efficiency, high error rate, poor stability

●Material turnover: low flexibility, time-consuming and labor-intensive, affecting production line production tempo

●Material management: It is easy to cause problems such as untimely inventory management, material shortage, and material leakage

From the receipt of raw materials, the turnover of the main warehouse to the line side warehouse, to the logistics or buffer of semi-finished products to assembly and packaging, and finally to the finished product inventory, it is related to the traceability of orders. The overall solution is to connect everything from hardware to system to form a closed loop.

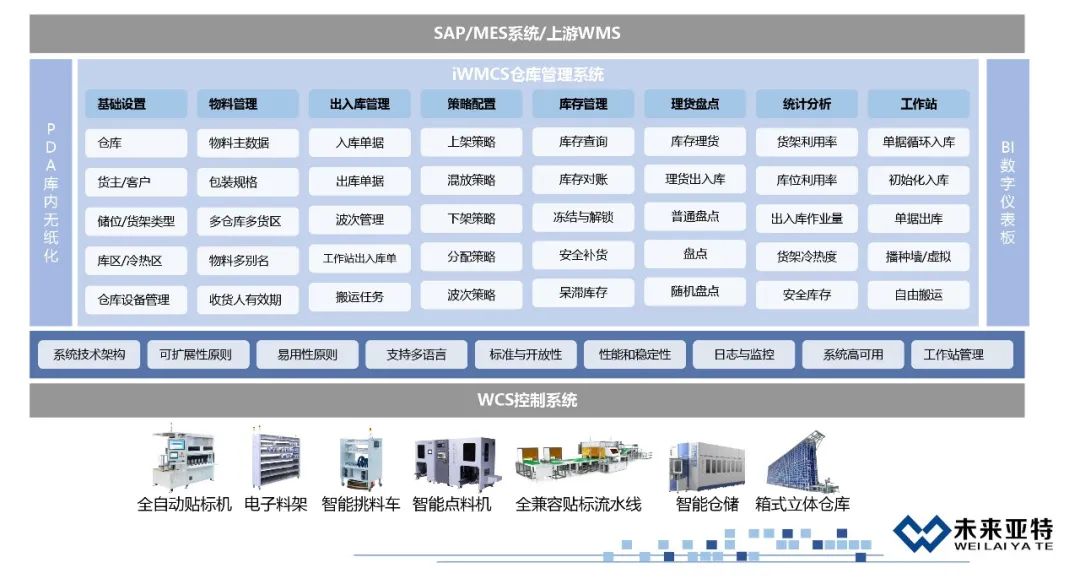

Intelligent warehouse management system

Future Att's own intelligent storage system software (iWMCS) system can be seamlessly connected with any WMS, ERP, MES, etc., forming a closed loop of data in the whole process, lean collaborative production, and realizing the production line receiving, sending, storing, and picking. Intelligent management of materials, etc., to create digital management covering the whole process of labeling, ordering, warehousing, sorting, distribution, management, assessment, etc., to realize the integration between different smart terminal devices, different system platforms, and different application scenarios Interconnection provides customers with a safer, simpler, more convenient and more comfortable personalized experience.

Project application case

Up to now, Future Att has reached strategic cooperation with many well-known enterprises, including 3C, machinery, automobile, retail, environmental protection, new energy and other fields, and its business covers East China, South China, Southwest China, North China, Central China, Taiwan, Hong Kong, Singapore, the United States , India and other regions, customers include Omron, Scud, Shuoge, Fenghua Hi-Tech, Panasonic, Foxconn, China Electronics, Yangjie Electronics, Changhong, Tricyclic Group, SUP, LCKT, ASLIN, Longking Environmental Protection, Lierda, Gaode Zhishen and so on.

The gathering of people at the event site attracted many manufacturers to come to consult and communicate, and introduce relevant technical knowledge.