ATT AUTOMATIC STORAGE SOLUTIONS

Solving the high-precision storage and retrieval issues in line-side warehouses.

|

|

High Storage Capacity,High density one position per unit |

|

High efficiency Next-generation dual robotic arms |

|

Temperature Control Equipped with temperature and humidity management module |

|

Intelligent Fully automated storage throughout the process |

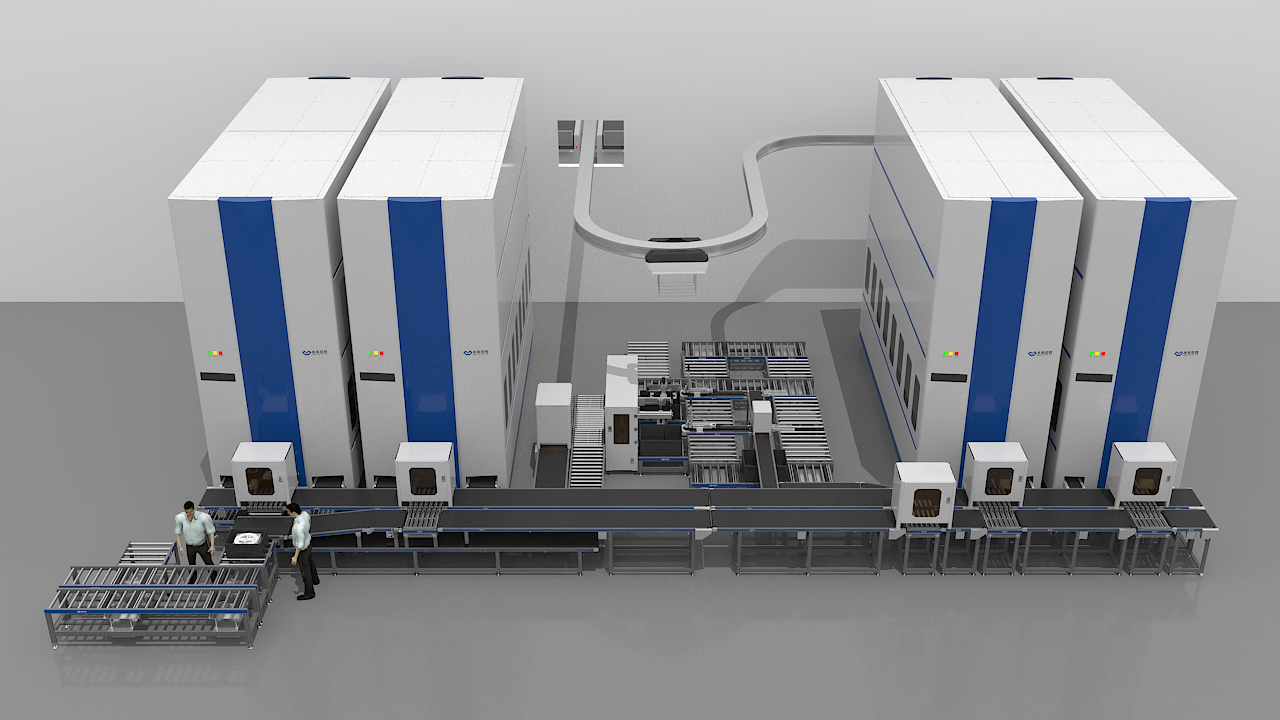

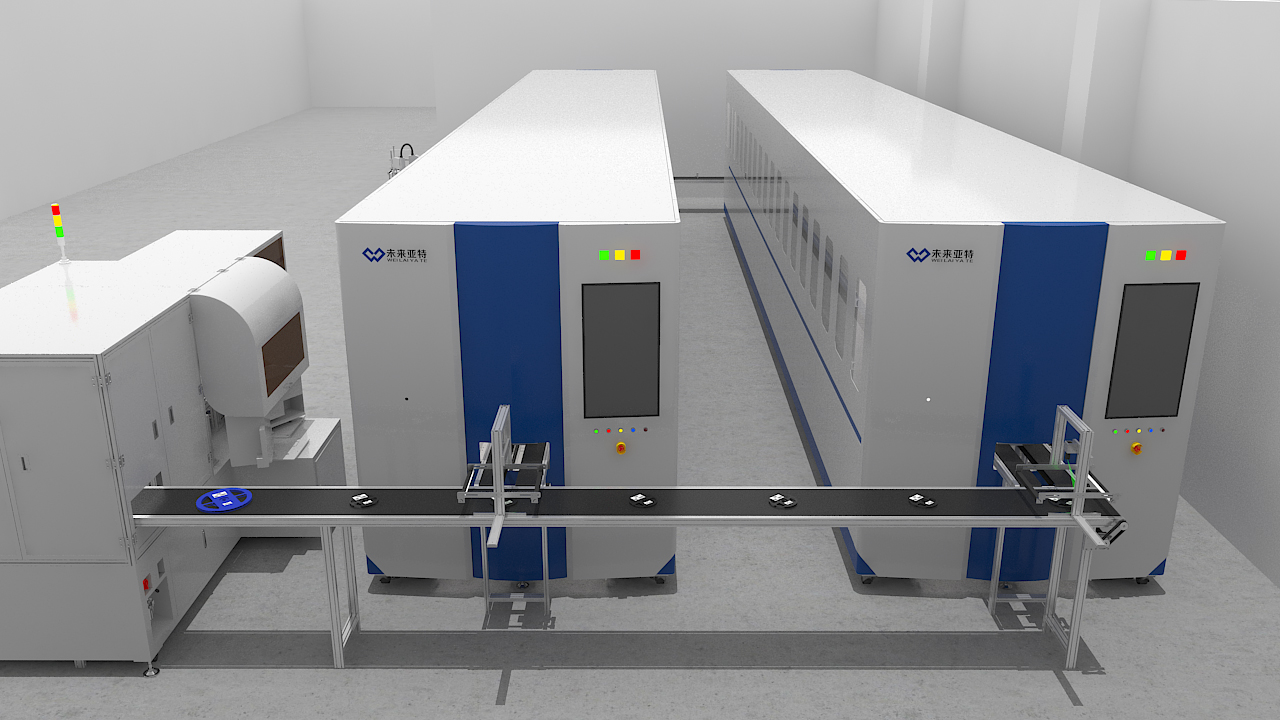

Application Description

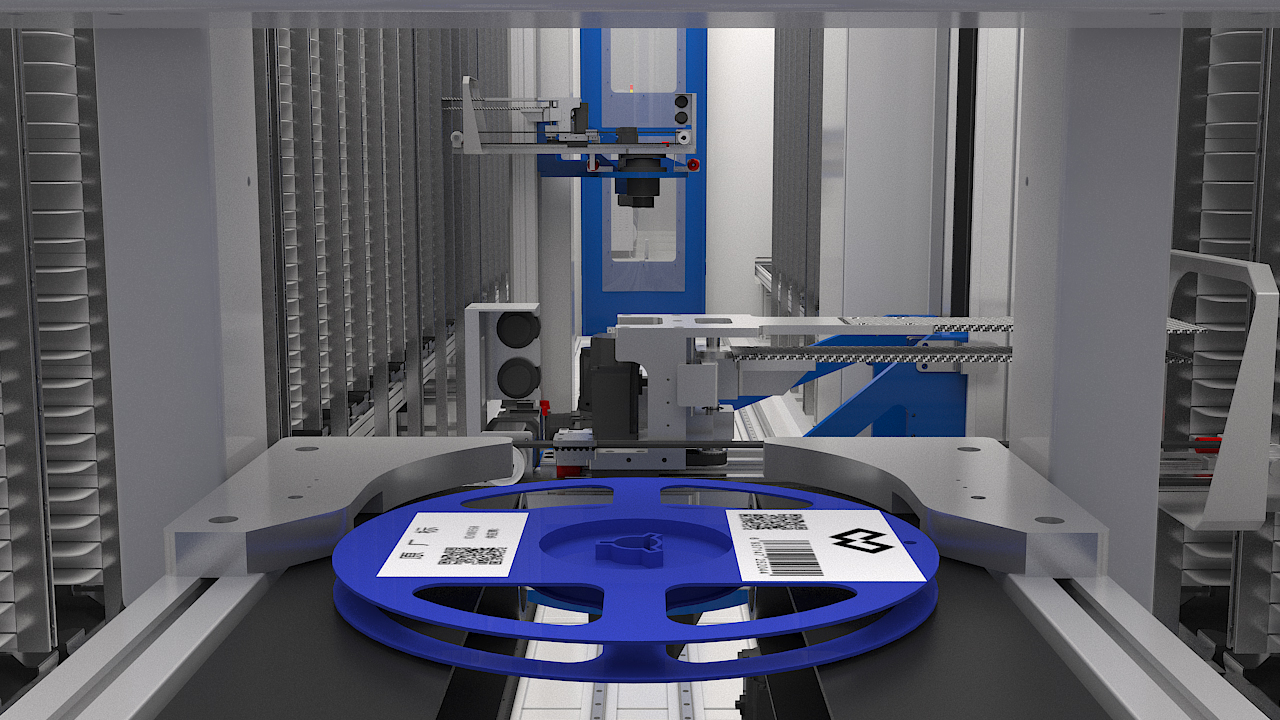

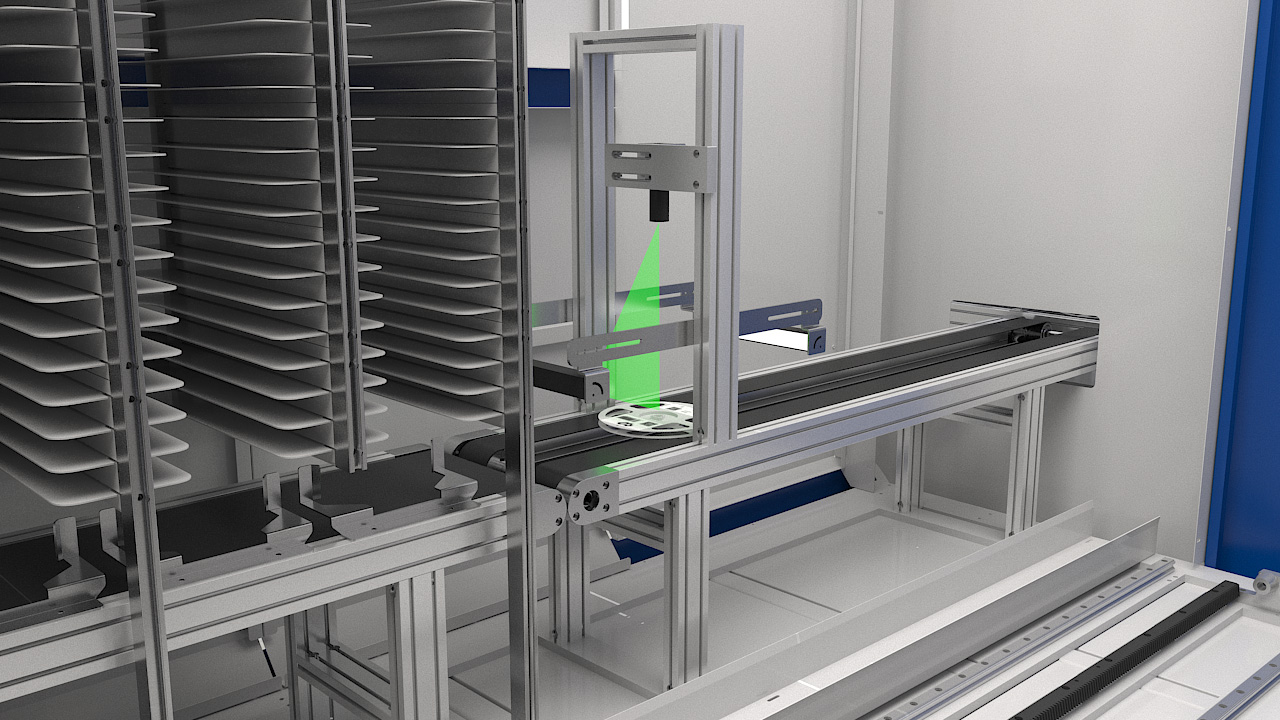

SMD Intelligent automatic warehouse (Line-side Warehouse)

Utilizing a single robotic arm, the warehouse operates fully automated throughout the process, enabling uninterrupted picking and sorting 24/7. This significantly improves the picking efficiency with precise positioning, ensuring safety and reliability. The warehouse is equipped with visual code reading and error prevention modules for inbound and outbound operations, preventing mistakes and enhancing data visibility in real-time. This improves material turnover efficiency, reduces operational costs, shortens customer delivery cycles, and ensures smoother production lines.

Processes such as incoming material storage, work order preparation, secondary sorting of leftover materials, returning leftover materials to storage, and asset inventory can be carried out using intelligent storage equipment instead of manual operations, greatly improving efficiency. The material traceability allows real-time querying of information such as part number, quantity, date, batch number, and supplier details. During production, the system can record each usage order, usage time, and analyze cost losses.

Application Scope: Suitable for the Electronic components industry (tray, bag, and box packaging) for raw materials,finished products, and semi-finished stagnant materials.

Adaptation Scenarios: SMT production workshops, line-side warehouses, and more.

|

|

|

700~800% increase pick and soft efficiency improved by 7~8 times |

unmanned operation 24/7 unmanned operation |

|

150% increase Improved space utilization, storage capacity increased by 1.5 times Unmanned operation |

100% reduction Reduced human intervention with accuracy rate of up to 100% |

Part Cases